Construction Management Labor shortage is a serious challenge – AI helps us get more from the workforce we’ve got

Labor efficiency in construction impacts timelines, costs, and overall project performance. Despite its global GDP contribution, the industry has seen just 1% annual productivity growth over the past two decades – this slow growth is often due to deeply rooted inefficiencies, labor shortages, and skill gaps within the workforce – all combined, resulting in costly delays.

What is labor efficiency?

Labor efficiency measures output (work completed) per unit of labor input (hours worked). Key metrics include:

- Output per Labor Hour: Measures work completed per hour. If a team lays 100 bricks per hour, this baseline can be used to measure improvements and chronic slowdowns.

- Work Area Utilization: Assesses workspace efficiency. Optimizing layout and coordinating the model in real-time can reduce clashes between trades or return visits, which otherwise may disrupt the workflow.

- Task Completion Rate: Tracks the pace of specific tasks. High completion rates indicate efficient processes, while low rates can signal areas for improvement.

- Consistency of Trade Output: Evaluates performance reliability across trades. Ensures steady progress and quality. Inconsistent output might reveal training needs, disputes, blocked work areas, or supply chain inefficiencies.

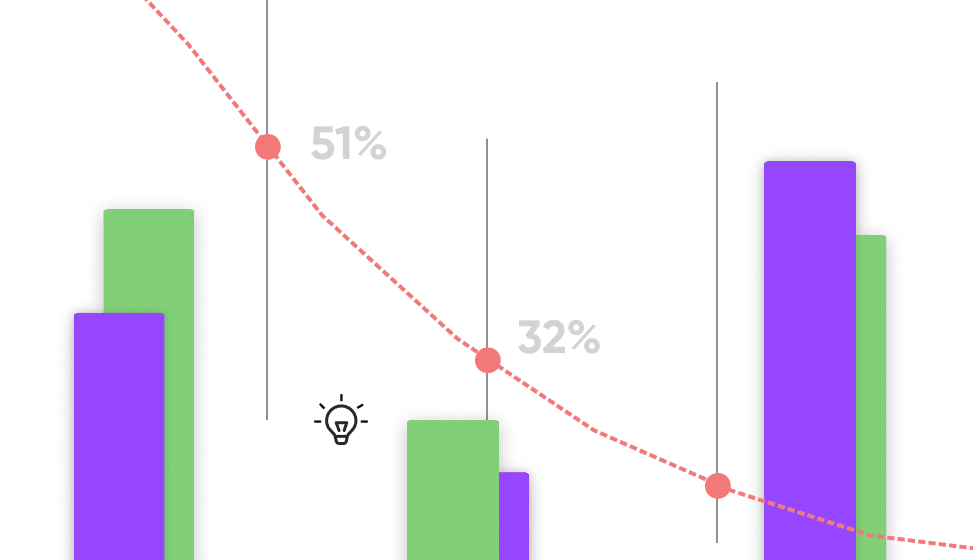

- Percent Plan Complete (PPC): Reflects project reliability by showing the percentage of tasks completed as planned. This metric helps in assessing how well the project adheres to the schedule, highlighting areas needing attention.

The big blockers

Recruiting, training, and then retaining skilled workers is essential, yet not sufficient. Demolitions, snags, and rework caused by incompletions or recurring errors consume valuable time and resources and can disrupt entire timelines. Enhanced quality control, up-to-date data sourced from the site, and meticulous planning can minimize such disruptions. Coordination issues, sequence disruptions, and work area clashes among trades tend to lead to delays; a single source of truth and objective insights can support workforce coordination and boost accountability.

How does AI improve on-site resource utilization?

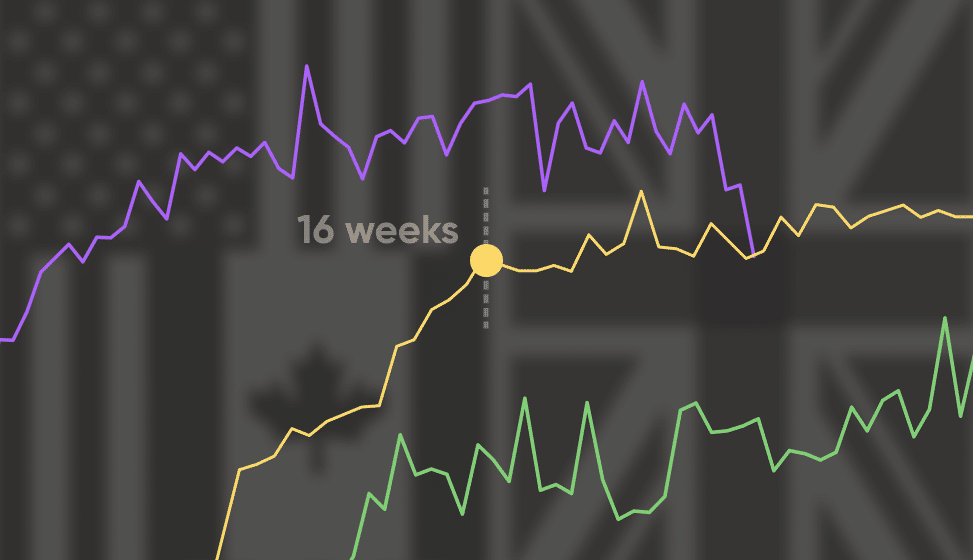

Predictive analytics forecast delays, allowing teams to mitigate those risks and recover time before greater disruptions occur. AI-driven data analysis supports informed decision-making, and dynamic short-term planning, significantly reducing delays. With recent tech advancements, project teams could be utilizing the following metrics in order to optimize utilization of resources:

- Automated progress tracking helps monitor Output per Labor Hour by providing continuous data on work completed and flagging incompletions, allowing for adjustments to be made early on.

- Predictive analytics can enhance Percent Plan Complete (PPC) by forecasting potential risks and bottlenecks, enabling preemptive actions to keep projects on track and make realistic plans going forward.

- Pace analysis can enhance Task Completion Rate by identifying process inefficiencies and providing solutions to streamline workflows and task sequences.

- Work Area Utilization can be improved by enhanced planning capabilities, relying on performance indicators instead of lagging indicators such as schedules.

- Collaborative progress tracking platforms improve communication, and help addressing issues by providing an objective single source of truth, enabling project teams to continuously monitor these key metrics, identify trends, and implement proactive measures before errors escalate.

The only possible path forward

The construction industry must embrace new methods and performance metrics if it wants to succeed despite labor shortages. Buildots' Performance-Driven Construction Management approach introduces a strategic overhaul by integrating advanced data analytics and key performance indicators into daily operations. These metrics not only facilitate more accurate project tracking and forecasting but also enable early identification and mitigation of potential delays, thereby enhancing overall project efficiency.

By entering this continuous improvement cycle and weaving new digital tools into the existing fabric of our established practices, we can overcome common on-site challenges, and set new standards for labor efficiency and trade accountability, and achieve sustainable growth.