Case Study How Sir Robert McAlpine and Vinci’s JV harnessed AI to improve collaboration and efficiency

One of our latest case studies dives into how IHP – a JV between Sir Robert McAlpine and Vinci – increased on-site efficiency and streamlined subcontractor activities using Buildots' AI-powered progress tracking platform on their Royal Bournemouth Hospital project.

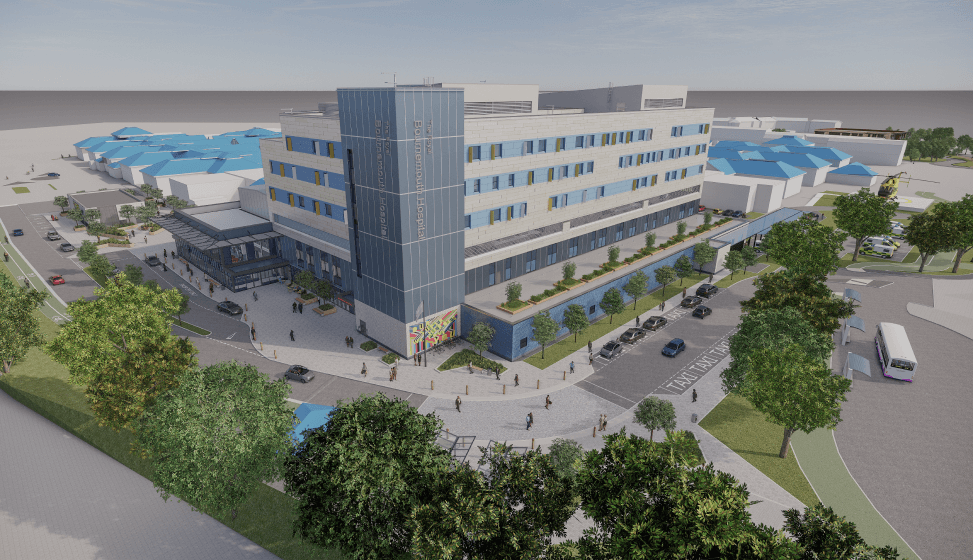

IHP, a leading provider of healthcare construction solutions, is an integrated joint venture between VINCI Construction UK and Sir Robert McAlpine. IHP is delivering a new ~£200m, 24,000 sqm extension at the Royal Bournemouth Hospital for a BEACH unit (Births, Emergency Care, Critical Care and Child’s Health) on behalf of University Hospitals Dorset NHS Foundation Trust (UHD).

Staying ahead of challenges: IHP boosts proactive behaviour

Traditionally reliant on time-consuming site walks and third-party updates that are prone to errors, IHP strategically decided to utilise Buildots as a comprehensive solution to enhance data accuracy, reduce delay risks, and eliminate errors before they escalate, resulting in greater site efficiency overall.

The Objectives: IHP strives to use automation to enhance productivity

IHP utilised Buildots’ technology to generate weekly time savings and benefit from powerful insights to forecast activities and delay risks while safeguarding the critical path. The AI-powered tool ensured:

Weekly Plan Optimization

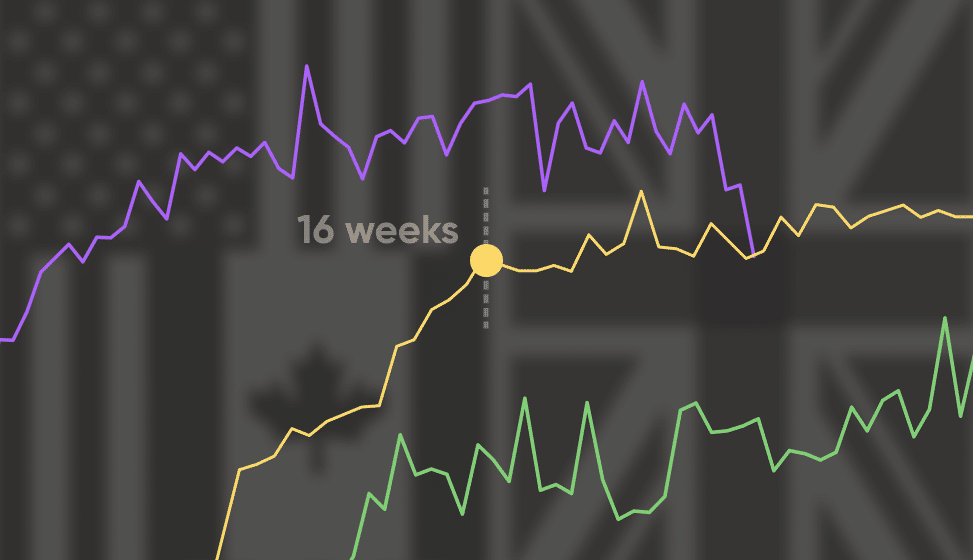

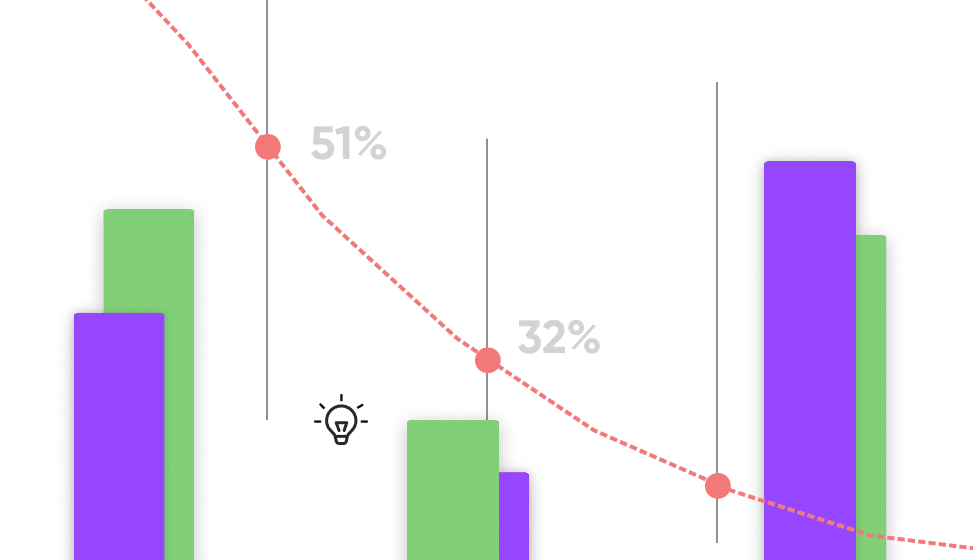

Boosting weekly goal achievement with Buildots regular data sets sourced straight from the site, helping IHP to increase success rates in meeting short-term objectives.

Delay Risk Mitigation

Identified deviations along the critical path in real-time, allowing projected end dates to be moved forward.

Enhanced Forecasting

Predictions made from automated progress tracking allowed for proactive and data-driven planning to ensure deadlines were met.

Subcontractor Collaboration

Facilitated trust-based relationships with subcontractors, offering full transparency on progress tracking and short-term planning.

The Outcome? Operational and collaborative excellence with Buildots Performance-Driven Construction Management

In conclusion, using the Buildots system’s automated progress tracking capabilities, IHP was able achieve:

Data Accuracy and Efficiency

Automated tracking reduces reliance on manual processes and minimizes human error.

Delay Risk Mitigation

Buildots estimated the expected delivery date based on average pace and identified activities that were blocking the sequence of works. Labour was then reallocated to bring forward the forecasted end dates which reduced predicted delays along the critical path.

Collaborative Environment

The tool facilitated trust based relationships with subcontractors, with full transparency on progress tracking and short term planning.

Enhanced Forecasting

Predictions made from automated progress tracking allowed for proactive and data-driven planning to ensure deadlines were met.