Maximize the benefits of BIM: Best practices for model setup

The benefits of BIM are extensive – and Buildots brings them to life. To help you maximize its value, here are three practical tips to focus on during the set-up phase.

Coordinating models across multiple subcontractors isn’t easy. Standards vary, scopes shift, and what’s in the model doesn’t always match what is getting built. But when BIM is structured right, the payoff is huge.

In a perfect world, every subcontractor model is structured, named, and categorized exactly the same. In reality? You’re juggling models from several different teams, each with its own standards, quirks, and inconsistencies. That’s just part of the job for BIM and VDC managers.

And yet, your model still has to perform, not just for coordination, but for downstream tools like Buildots that rely on accurate data to give actionable insights.

Here’s the good news: Buildots is designed to work with what you have. We’ve built powerful tools to clean, slice, and work with your models on our end. But the better the inputs, the faster and clearer the results and the less rework your team (and ours) needs to do.

In this post, we’ll walk through three high-impact ways to structure your BIM model for successful setup and downstream construction tracking, while pushing responsibilities back to subcontractors when appropriate. These aren’t theoretical goals, they’re battle-tested best practices we’ve seen deliver real ROI on live, complex jobs. I've worked as an architect, a design manager, and now as a senior VDC manager. So, rest assured that this is all based on real-world lessons, not theory.

1. Subcontractor models over design models: Aligning scope to site work

We all know that design models aren’t built for construction. They’re built for coordination, compliance, and client sign-off. And while they’re critical for early project phases, they don’t reflect how work will be carried out on site.

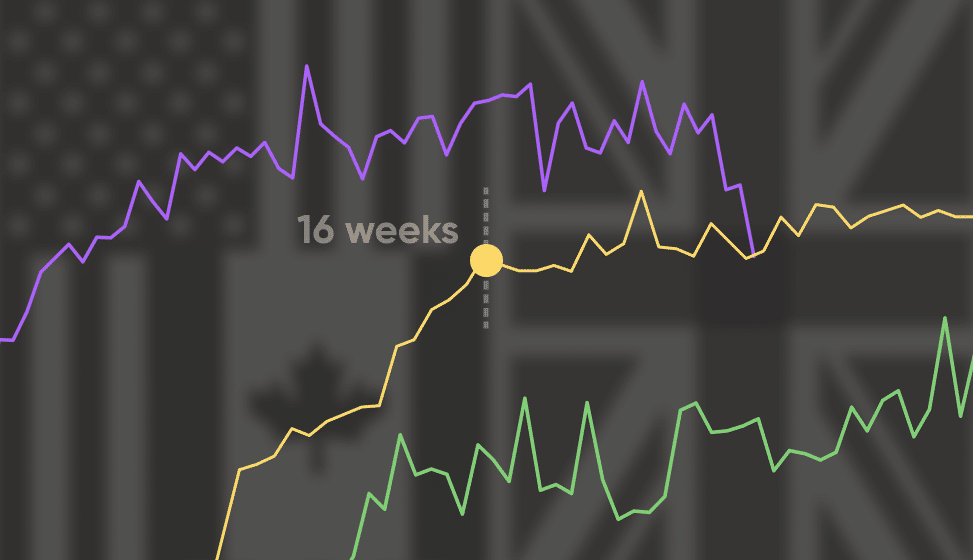

Buildots relies on models that align closely with what’s being installed. We are attempting to create a digital twin of your site, not just what’s been designed. That’s where subcontractor models come in.

When the model is built by (or at least structured with input from) the subcontractor doing the install, it reflects things like:

- Being constructability-ready: Subcontractor models show how systems will actually be built, with true sizes, clearances, and installation allowances.

- Fabrication-level detail: They often carry the level of detail needed for shop drawings and prefab, ie, joints, hangers, supports, far beyond design models.

- Data-rich properties: Subcontractor models usually contain the critical parameters (GUIDs, system types, install stages) that enable Buildots to track scope with accuracy.

- Temporary works: Things like temporary doors, cranes, buckhoists, or scaffolding brackets, which design models almost never capture but are critical for sequencing and access planning.

Why it matters

If Buildots is comparing site progress to a model that doesn’t match what’s actually being built, it either produces noise or requires modifications to clean it up. That’s time-consuming for everyone and totally avoidable.

What to do

* Require subcontractor contractors to provide their own models, not just markups or drawings.

* Scope model deliverables clearly in your BIM Execution Plan (BEP) during subcontractor procurement or buyout.

* Make sure subcontractor models stay current, updated regularly to reflect design revisions, RFIs, client-directed changes, and evolving site conditions

* Put QA/QC checks in place to confirm subcontractors are delivering what they’ve been contracted for, following the BIM Execution Plan and agreed modeling standards

Pro tip: Even if a subcontractor hasn’t finalized their install plan during procurement, encourage them to embed basic construction assumptions e.g., internal/external zones, rough-in components, Primary vs. secondary distribution, finishes components, temp/permanent scope. It gives your model structure from day one.

2. Structure and consistency: You don’t need perfection, but structure is a must

Your models don’t have to be perfect. But they do need structure if you want to maximize the benefits of BIM. A little consistency in hierarchy and naming goes a long way, not just for your BIM coordination workflows, but for tools like Buildots that rely on clean classification.

Common issues we see

- Components categorized under Generic Models

- Ambiguous element names like “Wall Type A”

- No consistent system > subsystem > category logic

- Curtain walls modeled without distinction between internal and external

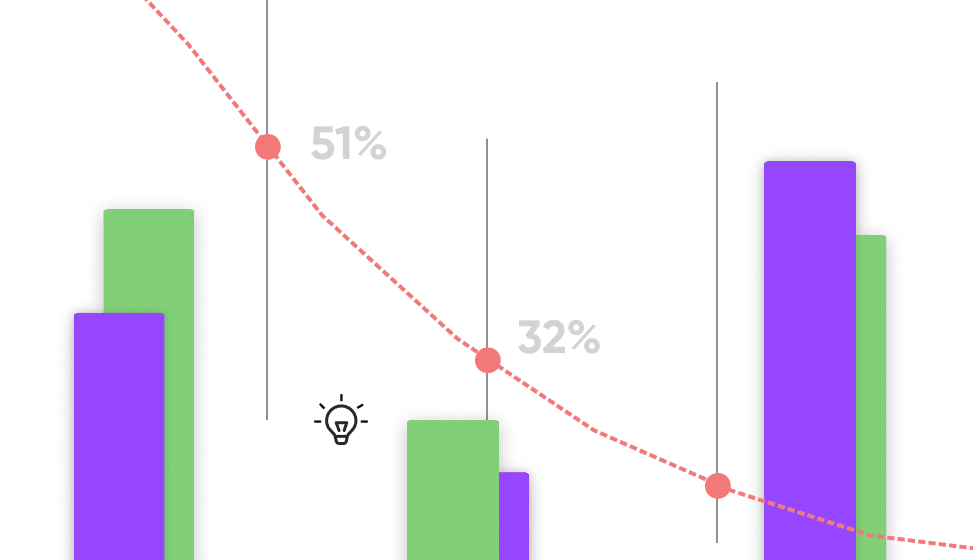

Architectural models often categorize doors and walls by type, but type alone doesn’t reflect how they’ll be built. A fire-rated door and a temporary plant-room door may both fall under the same type, but they’re installed at different phases. The same goes for walls: models are usually split by wall type, not by construction methodology. For Buildots to track accurately, doors and walls need additional properties that show install logic. For example, pre-fix vs post-fix doors, or top-down vs full-height wall assemblies.

Buildots isn’t rigid, we’ve built tooling to overcome these challenges. But the more structured your model, the faster we can surface insights without heavy customization.

What to do

* Enforce naming conventions across subcontractors (no “Generic 01” allowed).

* Split elements by install logic (e.g., wall types split by build sequence, curtain walls by scope).

* Define a Primary Tracking Property per discipline, the key attribute Buildots can use to group and analyze components.

Pro tip: Use shared parameter templates across subcontractors. If everyone’s using the same structure, Buildots can apply logic faster and so can your QA/QC tools.

Smart naming conventions

Doors → Install Stage: Pre-Fix / Post-Fix / Temporary

Ductwork → System Type: Supply / Return / Exhaust

Walls → Construction Method: Top-down / Full Height / Corridor walls

3. Connecting model objects directly to construction activities

The benchmark is a model structured around installation. It may sound ambitious, but we’ve seen it delivered on large projects. Because Buildots tracks what gets installed, when, and where, every component in the model must be uniquely identifiable and tied to a specific install activity.

When a system spans multiple install phases or visits without clear metadata, it becomes challenging to capture the system and all its components as they are actually planned to be installed. As a result, you may not see the full scope of the activity because the platform is limited by how the model has been structured. For example, if there is a discrepancy or missing info between how ducts are categorized versus how the duct fittings and duct accessories have been categorized. Likewise, if cable trays are modeled as generic objects with no GUIDs, they become invisible to the platform.

Consider this real-world example. On a large hospital project, the VDC team added a custom property to wall objects to identify those requiring “top-down” install, a 4-foot drop from slab to allow MEP subcontractors to run services before drywall closes the zone. This wasn’t in the architect’s model, but it was crucial, as the activity was on the critical path. By flagging these walls early, Buildots could track them as a distinct subcontractor visit, enabling better install sequencing, coordination, and risk

What to do

* Every tracked component must have a unique identifier (In Revit, this is GUIDs).

* Wherever possible, split or tag components with the Activity Name or the phase of installation.

* Split multi-activity components into separate, scoped objects.

Pro tip: Even if install logic evolves, your model should remain your source of truth. Keeping it aligned with what is happening on site accelerates insights and simplifies future FM handover.

Examples

MEP: MEP systems should distinguish between riser mains and floor-level distribution, since risers are critical-path and usually installed early, while branch piping follows later after framing. Where relevant, also separate main trunks from secondary branches. Mains go in first, branches afterward.

Walls: Split top-down walls (slab-to-4ft drop for MEP access) from full-height partitions if relevant. This is because top-down walls are a sequencing requirement on critical path jobs, not usually captured in design models.

Doors: Separate temporary/early install doors (e.g., plant rooms, logistics routes) from finish-stage doors. This helps Buildots reflect different install visits instead of lumping all doors as one phase.

Floor finishes: Break out base layers (screed/leveling), intermediate finishes (tile/stone), and final coverings (carpet/vinyl). Why: Each layer is installed at different times and by different subcontractors.

Laying the groundwork for construction-ready 3D models

No BIM manager should be stuck with messy subcontractor models. With a solid BIM Execution Plan, clearly scoped subcontractor responsibilities, and a few foundational modeling practices, you can shift from reactive cleanup to proactive oversight.

Buildots isn’t asking for perfect models. But when your BIM is structured with install logic in mind, it becomes extremely powerful, giving your team visibility, smoother tracking and rock-solid actionable insights.

You’re already doing the heavy lifting. These best practices make the benefits of BIM go even further, giving your team real results, and your project a real edge.

Ready to see how AI can help your team do more with less? Book a Buildots demo today and see what performance-driven construction looks like in action.