Craft meets science AI and data in project scheduling

It’s a tale as old as construction itself: A project is sold – planning and design commence, permits are issued, and budgets are allocated. But then—the issues arise! Work gets delayed, costs escalate, and before you’ve even made your first cup of coffee, you’re already behind schedule.

How does this happen every single time? How come every project, regardless of location or contractor, ends up this way?

It starts with the ‘chicken-and-egg’ problem of construction scheduling

Over the past several months, we've published a series of blog articles as part of our Performance Driven Construction Management (PDCM) framework. Each post deals with different aspects of construction management, exploring how we can run projects more efficiently using accurate data. One of the major challenges we encounter in construction scheduling is a classic chicken-and-egg problem: you can't create a fully developed schedule until the design is complete, but you're reluctant to invest in an extensive and costly design phase only to find out the project is unaffordable. This leads to low-quality designs and inaccurate schedules—not the best way to start a project.

But how do we do it better? Are you building the schedule based on a database of past performances from similar projects, including trade-specific data, benchmarks for quantities per week, and historical performance metrics? Probably not. Wouldn't it be great if you could? The obvious answer is 100% yes, but until now, we didn't have that option.

4D BIM and AI-based progress data as the foundation

AI-based progress tracking for construction is relatively new in our industry's history. Just a decade ago, this concept didn't even exist. It took us some time to work out how to systematically connect 4D BIM (models and schedules) along with 360 project “reality captures” using Artificial Intelligence. We came up with precise AI-based progress tracking, but it didn’t

end there. But now we have entered a new era, an era where project leaders are capable of predicting delay risks well in advance, allowing them to prevent these delays with corrective plans and immediately measure the impact of those plans.

Project schedules should be realistic, ambitious, and based on past data

Enhancing project performance is only one element of the project risk management equation. The other aspect involves consistently producing project plans that dynamically align the entire supply chain around realistic yet ambitious goals. For that to happen, we must take past performance into account when crafting and adhering to these plans:

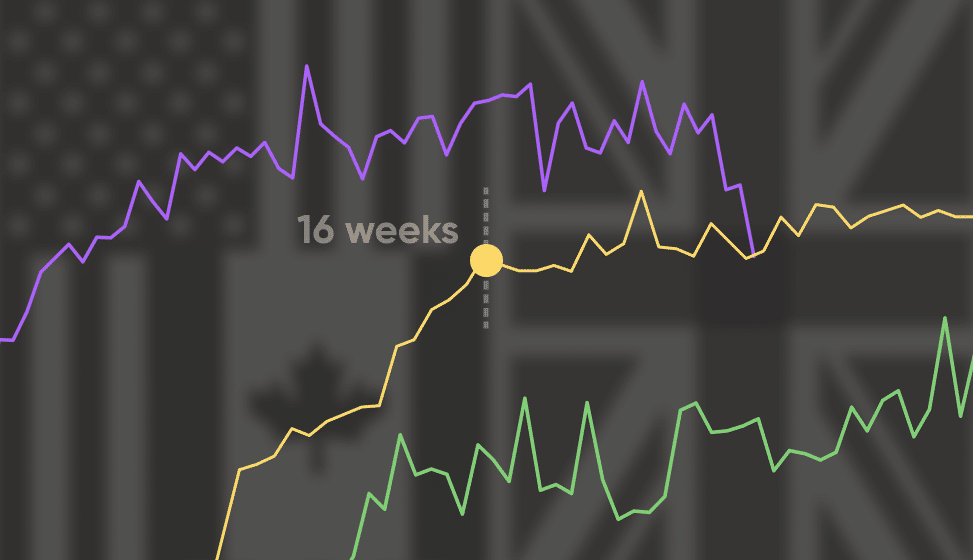

- 4D & past pace benchmarks – Precise progress data, connected to schedules and 3D models, offers pace benchmarks. It can be as simple as “How long does it take to install 1000 linear meters of supply duct?” or even as complex as “What was the median pace for drylining in commercial construction in the London market in 2024?”

- The performance of specific trades – When evaluating a specific trade, it's valuable to seek benchmark data to understand its historical success and failure. Analyzing the trade across various projects can also provide insights into recurring patterns.

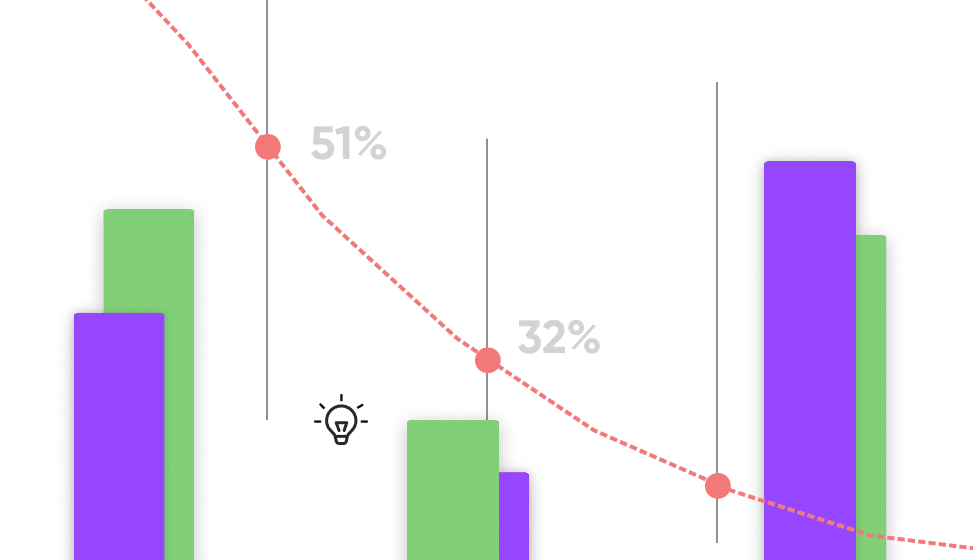

- The result of different scheduling options from past projects – Schedule optioning, or “What-if scenarios” are valuable practice. Evaluating these scenarios with performance data from past projects allows us to assess them before the plan is finalized. This way, you can weigh each option against reality.

The practices mentioned above apply to both initial planning in the pre-construction phase and mid-project schedule revisions. The key to successfully navigating a project to its finish line is to integrate project needs and limitations with knowledge gained from past projects, backed by progress-based facts.

The future of construction planning: a blend of craft and science

For decades, building and maintaining a construction schedule was a craft performed by the experienced and wise. Entering the era of AI in construction shows us, however, that science can elevate this craft for much better results. By integrating AI-powered data from the job site, and historical benchmarks, we can create achievable yet ambitious plans that align the entire supply chain, taking into account bottlenecks, and mitigate risks effectively. If we embrace these technological advancements, construction planning will be more predictable and efficient, paving the way for a new era of project management excellence.