Complete faster, spend less The new era of AI-driven data center construction

Have you faced delays in your data center projects due to miscommunication or lack of visibility? In this blog, Barak Gur-Arie explains how AI progress tracking can help data center owners shift their stance from reactive to proactive.

The global data center market is exploding, driven by our insatiable appetite for computing power to drive cloud, IoT, and AI applications. This puts data center owners under unprecedented pressure to deliver new projects quickly.

In data center construction, time-to-market is everything. A delay in bringing a facility online can translate into millions of dollars in lost revenue and hinder owners’ ability to scale operations, especially when the data center supports essential cloud or AI services. The stakes are high, but successfully managing these complex, multi-phase projects isn’t easy for owners.

Poor visibility and subjective reporting: Why today’s data center owners are always on the back foot

Constructing a data center is far more than just erecting a building. It’s about orchestrating multiple sophisticated systems (cooling, electrical, IT infrastructure, etc.) under tight timelines and across different specialist teams. Each data center is really two different construction projects – the base build and the tool installation. Managing these intricate phases can cause problems. Even a small error in sequencing or communication can lead to cascading delays, cost overruns and rework.

Today, most owners can do little to prevent these problems. That’s because they rely on subjective reporting from general contractors and trades to know what’s happening onsite, which forces them to be reactive and prevents them from ‘getting ahead’ of crises.

How can we move from delivery uncertainty to total predictability?

Given the scale of financial risk taken by data center owners and the time pressure they face, it’s no surprise that many want to play a more active role – asking GCs hard questions and working together to achieve project success.

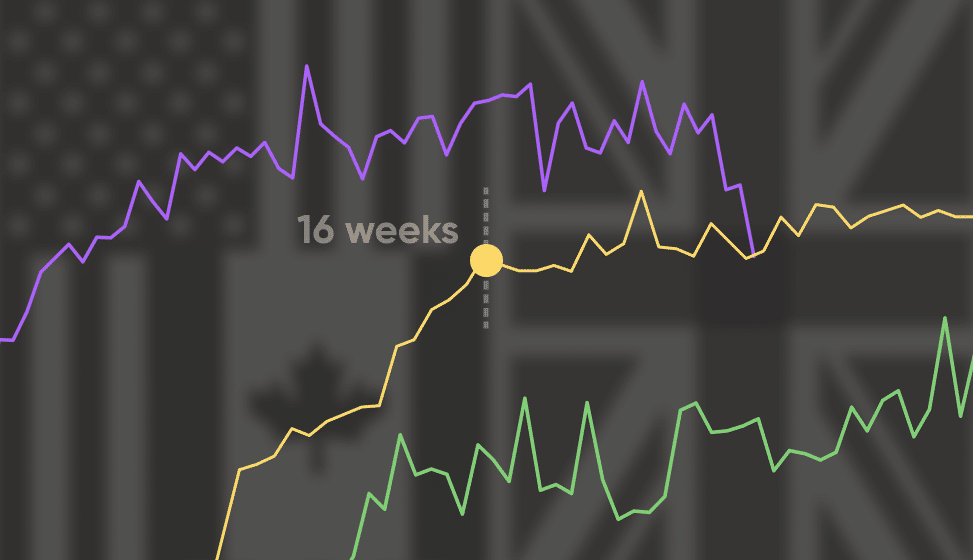

This is precisely what AI progress tracking delivers. The technology relies on cameras regularly capturing on-site footage which is compared in detail to the BIM model and work schedule, transforming raw footage into detailed, up-to-date project insights.

AI progress tracking gives owners the gift of visibility and predictability. When you can see what’s really happening onsite, you can play an active role in identifying and resolving challenges. Here are just a few examples.

Predict delays, so you can accelerate time-to-market

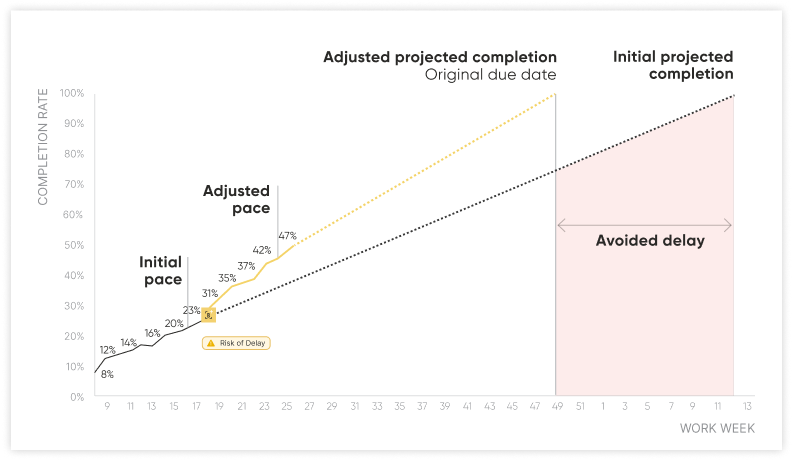

By comparing actual progress with the planned schedule, Buildots’ AI-powered progress tracking platform can detect when construction is falling behind. This alerts data center owners to potential slowdowns and delays to project milestones as early as possible, allowing them to work with contractors to keep the project on track.

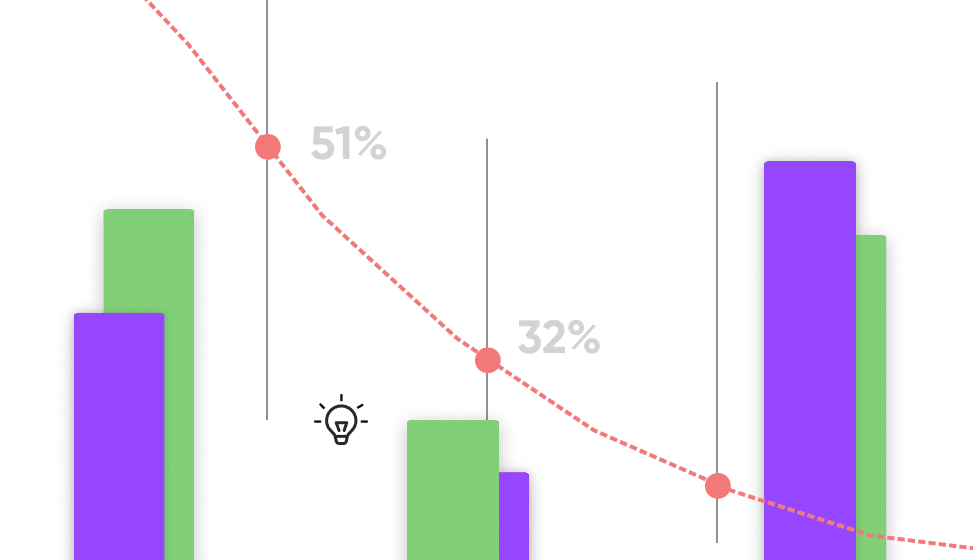

Only sign off work that’s actually been completed

As an owner, you never want to sign off on an area that hasn’t been completed. However, spotting loose ends with the naked eye can be difficult. By comparing work done to your BIM, AI helps you spot unfinished work and verify that trade partners have addressed it.

No nasty surprises: Build the most accurate project possible

Data center owners need projects to stay true to the BIM model and for any revisions to be reflected accurately in the build. After all, even minor model deviations can have a huge impact on maintenance over the years. AI progress tracking platforms help analyze every element in the model and indicate if it was installed properly, so you can rest easy.

Benefit from a detailed ‘paper trail’

AI progress tracking platforms create a reliable, detailed record of construction progress, showing you how your project progressed from day one until completion. This helps owners comply with demanding industry regulations and ensures a clear audit trail.

AI progress tracking in the wild

Industrial and data center owners are experiencing all these benefits with Buildots. Consider the example of Intel, which uses the platform across its global semiconductor fab construction projects. On average, it has avoided four weeks of delays per fab since implementing Buildots.

Assaf Harel, DigiT Delivery Operations Sr. Manager, Foundry Construction Enterprise at Intel Corporation, gave this opinion of the platform, “Adding Buildots to our fab construction project has enhanced our data-driven management approach and controls. Early warnings for issues and delays have resulted in significant savings in time and cost.”

The bottom line

AI-powered progress tracking is a central ‘control tower’ for data center owners. It empowers them to maximize predictability, minimize financial risk, and be confident they’ll complete their projects on time.

Discover how AI-powered progress tracking helped Intel reduce delays and improve efficiency. Explore the full case study here.