Project Management Improving project performance through objective data

Delays are a prevalent issue in construction, impacting over 75% of projects with an average setback of 20%. When we consider two-year projects, this translates to a delay of roughly 20 weeks or five months per project.

As Peter Munn, Project Director at Sir Robert McAlpine, a construction industry leader, puts it, “Delays are the age-old construction problem – caused by skill shortages, breaking sequences, leaving incomplete work behind, and looking at the project through too many different lenses. We need something objective. That’s the missing piece.”

Empowering operational leaders to optimize performance

Buildots ran a webinar inviting experts Peter Munn, Project Director at Sir Robert McAlpine, and Paul Quinnell, Senior Project Manager at Wates Group, to share their experience of adopting a Performance-Driven Construction Management (PDCM) approach to battle those notorious, all-too-common delays.

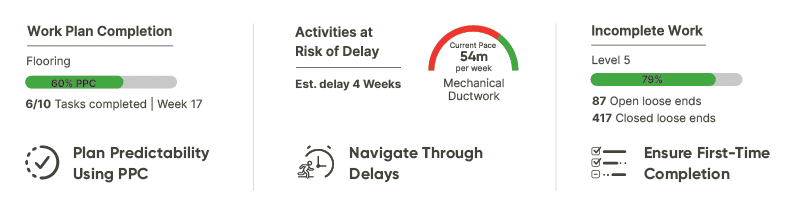

PDCM is a response to deeply-rooted difficulties on the ground and it provides a proactive methodology born from real-world pain points. PDCM introduces a strategic overhaul in construction management by integrating advanced data analytics into daily operations. Key performance indicators (KPIs) like Area Utilization, Percent Plan Complete (PPC), and Delay Risk Potential become invaluable tools for project managers. These metrics not only facilitate more accurate project tracking and forecasting but also enable early identification and mitigation of potential delays, thereby enhancing overall project efficiency.

First-hand accounts of the PDCM impact

Those who decide to apply AI early on will make their on-site operations more efficient. “That's what this all started with,” emphasizes Paul Bamforth, webinar moderator and Head of Strategic Accounts at Buildots. “Becoming better through undeniable project data. We must distill this information and provide it to the decision-makers.”

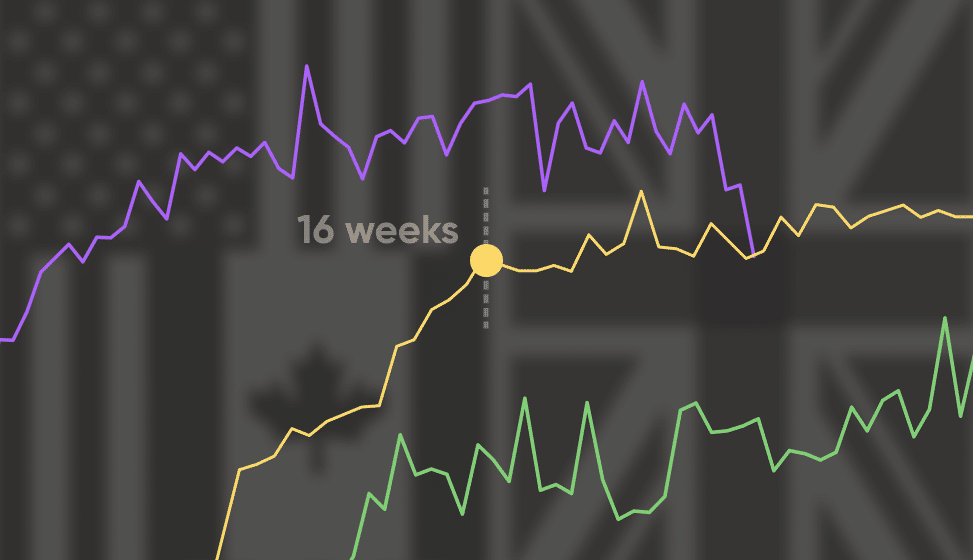

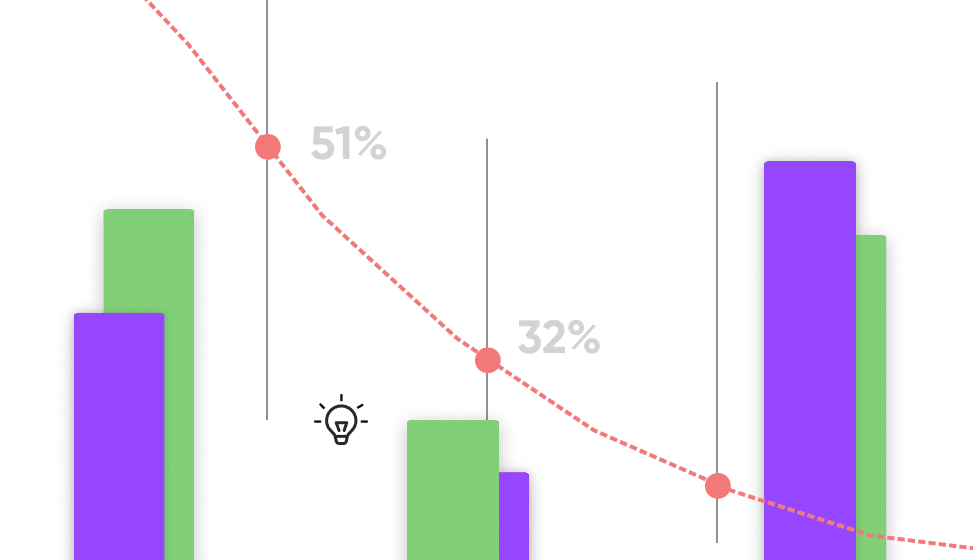

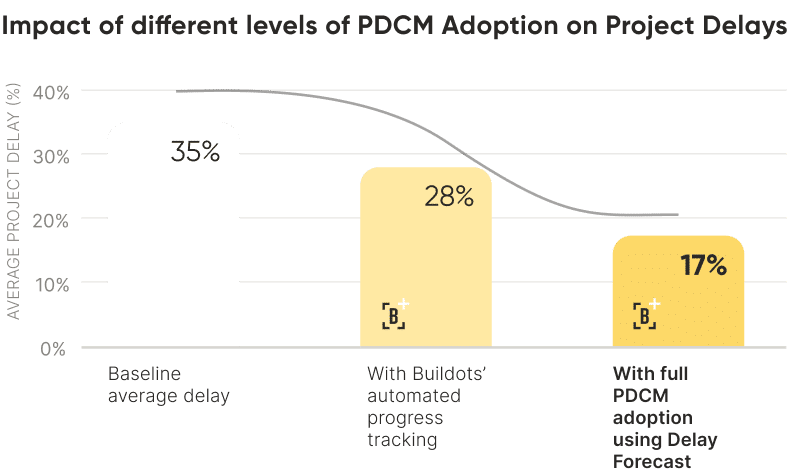

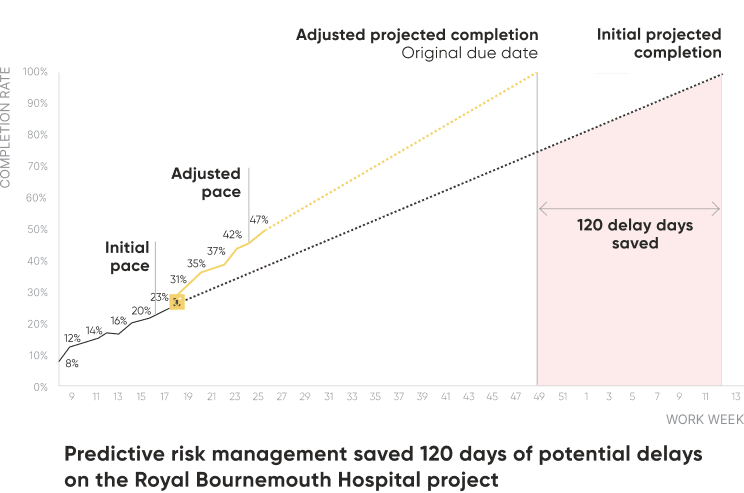

Adopters of Performance-Driven Construction Management (PDCM) have observed substantial reductions in project delays, with reports of up to 50% improvement. Typically, projects experience about a 37% delay, but with basic Buildots implementation, this decreases to 28%. Companies fully embracing advanced features like Delay Forecast and Work Planning have cut delays to just 17%, demonstrating the power of predictive insights. Through the implementation of AI-powered, predictive analytics and data gathered on-site, new tools such as Buildots’ Delay Forecast have enabled teams to spot trends in the current rates of progress and pace, resulting in tangible reductions in project delays.

A noteworthy collaboration discussed during this webinar was Buildots’ partnership with Sir Robert McAlpine (SRM), spanning nearly three years, encompassing multiple projects and over 260K sqm (2.8M sqft) of construction area. When using Buildots for enhanced forecasting on the Royal Bournemouth Hospital, the early proactive interventions and customized mitigation plans resulted in a reduction of 120 days of projected delays.

The dreaded word of ‘change’: It’s about a mindset

Adopting new technology and innovative, practical strategies such as PDCM is not about changing everything—it's about enhancing our current processes. Or as Paul Quinnell aptly puts it, “Let’s not treat AI as a threat. Let’s look at this as an investment to optimize our operations. It's not an easy gig, but we make it harder for ourselves if we fear change.”

Surprisingly (or not), the unique characteristics of our industry make it exceptionally suited for adoption of AI technologies. Construction operations have clear optimization targets such as faster project delivery, increased profitability, and enhanced safety. The success of these projects depends on precise, proactive control over numerous moving parts and a vast supply chain, “We want supply chain partners to come in early and commit to a collective delivery of the project. This optimizes our operations and reduces conflicting views about project progress,” stresses Peter Munn.

Conclusion: No longer accepting the unacceptable

“The facts speak for themselves. We need to embrace technology. We're living in a digital age, and it has benefits. We've got to grasp it and move forward – rather than be left behind,” Paul Quinnell concludes. This is what Performance-Driven Construction Management (PDCM) practices are all about. Performance indicators and reliable data can reduce unexpected issues on site. They have the power to foster a dynamic culture of continuous progress, finally closing our industry’s productivity gap. Construction teams can operate with certainty – proactively tackling pace issues and adjusting project timelines with incredible accuracy. Or as Peter Munn concludes, “If we keep doing it the old-fashioned way, there will always be a lot of opposing views over who did what, where, and when. Let’s take the bias out, let’s take the leg work out – and instead, let’s put the data in.”