Ending the Era of Schedule Slippages What is Predictive Risk Management?

Construction sites are places where everything happens at once and everything depends on someone else. Deliveries are rolling in and out, site managers juggle decisions on the fly, and trades compete over work areas. It’s a dynamic ecosystem where every hurdle can send ripples down the entire task chain and issues arise unexpectedly.

Procurement problems, labor availability fluctuations, and sudden design modifications are just a few everyday examples that can cause cascading errors. They're not mere hiccups; they have the potential to derail entire timelines, leading to the notorious ‘Schedule Slippage' every project manager dreads.

But what if we knew about bumps and bottlenecks ahead of time, navigating our projects toward calculated success with unwavering foresight? Isn’t it time we stopped accepting delays as an integral part of construction projects and start tackling them head-on?

That’s the secret behind Buildots’ Predictive Risk Management Solution (PRM). PRM is a transformative solution that aims to enhance common construction management as we know it in three distinct ways: Identifying a risk, creating a plan to avoid or resolve that risk, and effectively executing this plan before the risk becomes a problem.

1. Analyzing Progress, Assessing Risks

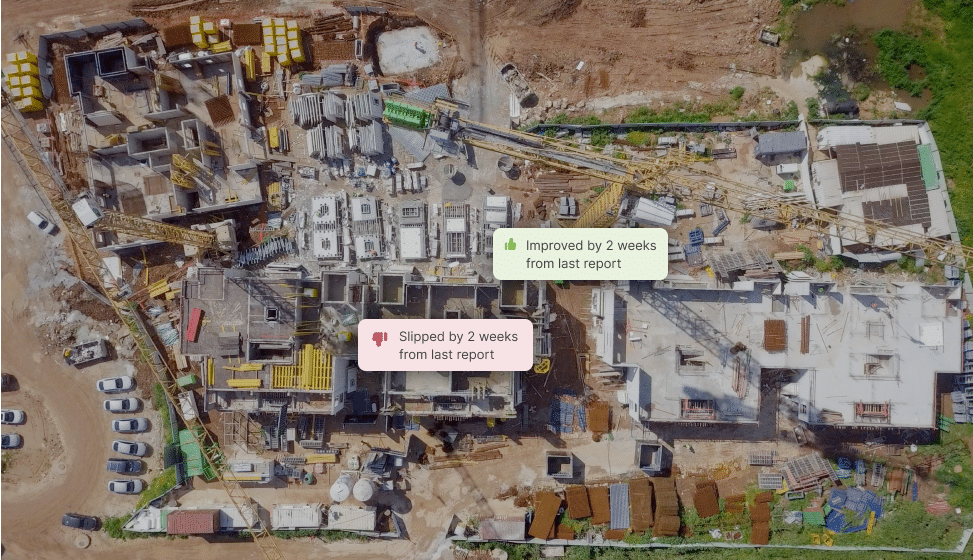

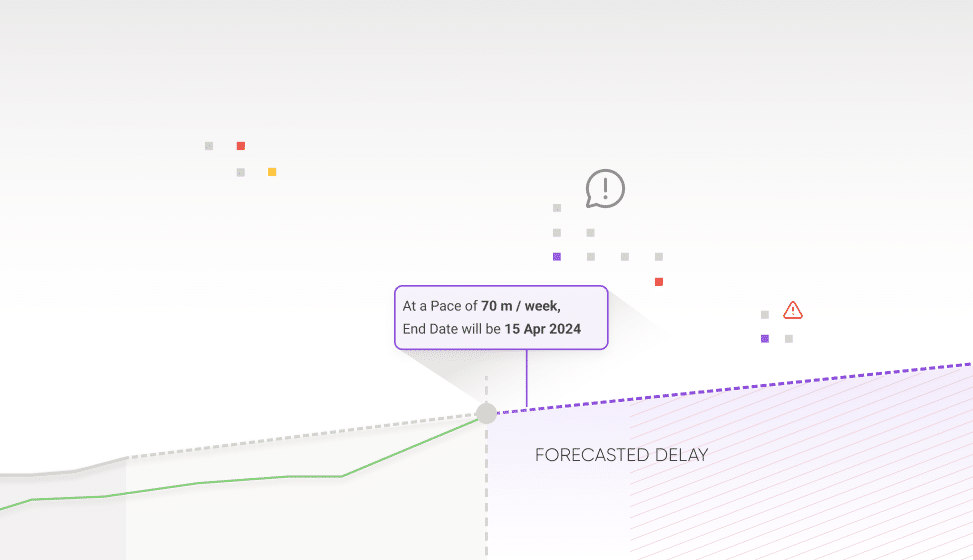

Analyzing pace and progress of each activity, Buildots' AI-powered technology acts as a predictive tool, estimating the end dates of individual activities and gauging associated project risks. This newfound visibility equips construction professionals with the power to be proactive, addressing issues before they snowball.

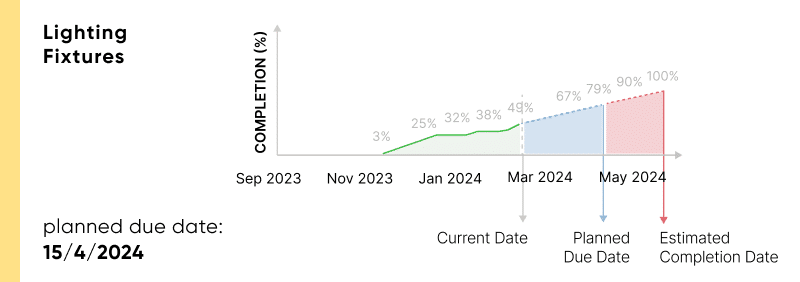

Let's jump into a real-life scenario: The graph below illustrates the installation of lighting fixtures. In this particular instance, 2,851 units needed to be set up across approximately 25,000 sqm and spread over 10 floors, with a deadline for April 15th, 2024. Using Buildots’ pace analysis tool, project managers quickly identified a potential setback of around one month if they maintained the current pace, giving them the opportunity to adjust their course of action – and pace – early on.

2. Crafting Recovery Plans

Leveraging real-time analysis, predictive projections, and a keen understanding of the project's critical path, we are now ready to develop personalized recovery plans and formulate customized recommendations for optimal pacing within each activity. Equipped with such strategic foresight, we can now determine the exact pace required for every task to align with the overarching project goals.

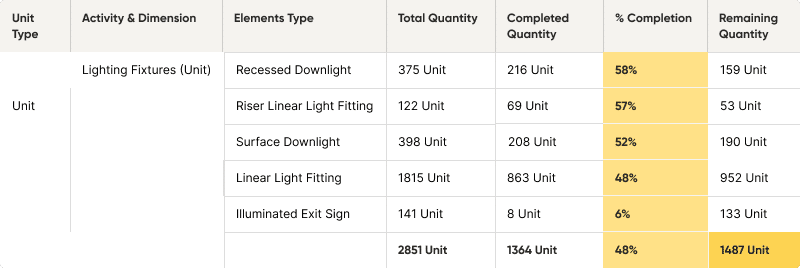

The result? A proactive methodology that not only prevents potential delays projected down the line but also acts as a shield against the emergence of new setbacks. Considering our lighting fixture installation example through a recovery plan lens, we observe that out of the total of 2,851 units, 1,487 units remain for installation. With a mere 6 weeks left for the project manager to complete these fixtures to stave off the delay, it necessitates aiming for approximately 250 units per week.

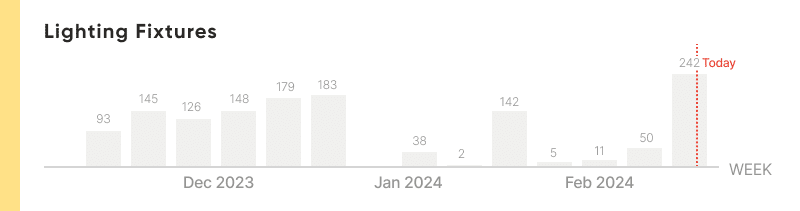

Armed with the necessary weekly target, the project manager can now review the actual installed quantities from recent weeks. This analysis reveals that, with the exception of the previous week, the trade's actual pace consistently fell short of the required pace. To fully recoup the lost time, they must accelerate their efforts by either increasing labor resources or optimizing existing manpower utilization.

3. Achieving Outcome Certainty with ‘Percent Plan Complete’ (PPC)

Finally, equipped with our tailored recovery plan, projects must meticulously oversee their weekly plans and trade commitments to ensure the seamless execution of these recovery efforts. Within Buildots' weekly productivity analysis lies the Weekly PPC (Percent Plan Complete), a crucial bridge between planning and execution. By evaluating planning certainty and productivity on a weekly basis, construction teams gain an exact measure of progress. This data-driven approach fosters optimization and ensures alignment between initial plans and realized outcomes.

It's decision time: continue the age-old pattern of accepting delays or embrace methodologies like ‘Predictive Risk Management' (PRM) to refine your project management, avoid delay fines and broken promises, and navigate your projects within budget and timelines.

Intrigued by groundbreaking construction management approaches? Find out more in our deep-dive whitepaper packed with real-life case studies.