Lean Construction Evolved The Critical Role of Performance-Driven Insights

In any industry, minor improvements in efficiency, innovation and operational processes can have an enormous influence on profits. Lean construction promises a future of reduced waste and maximized value – but how can it ever reach its full potential without the clarity performance data provides?

The Lean Vision

The ideal state of a Lean construction project is a continuous, uninterrupted flow that is reliable and predictable. At its core, it targets two main goals: Eliminate waste – not only the physical but also time and resources – and drive value across the entire construction lifecycle, from design through completion.

The true purpose of lean management encourages continuous improvement — each construction activity is analyzed meticulously, removing any unnecessary steps, roadblocks, and redundancies, aiming to make project delivery efficient, sustainable, and timely.

Where Is The Gap?

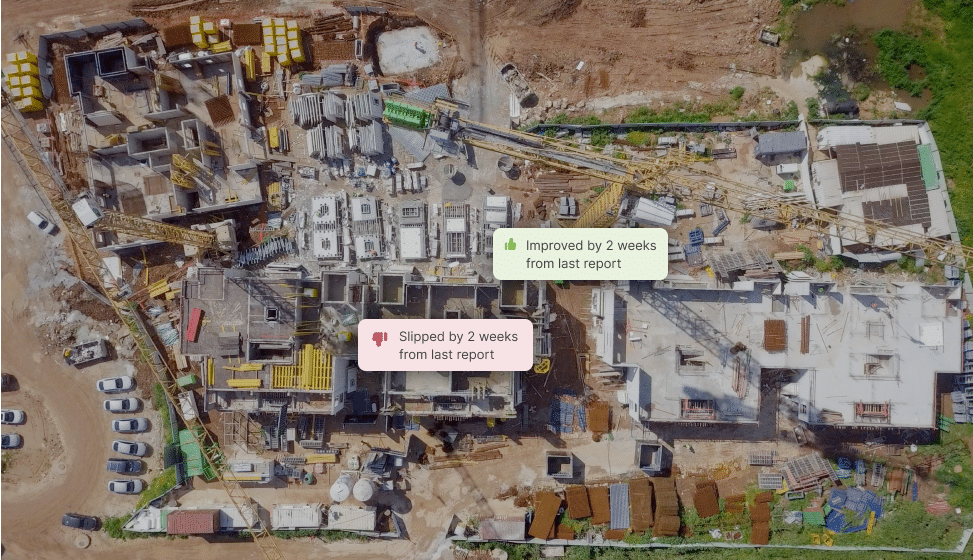

Boosting project performance with the help of lean principles needs accurate site data that is always up-to-date. This is the mantra we need to embrace if we want to enter the new era of modern construction: Improvement needs precise measurement; Precise measurement needs reliable data. Lean approaches can only be effective if they are provided with the accurate set of information from the construction site.

Performance-Driven Construction Management Completes The Lean Vision

Performance-Driven Construction Management (PDCM) promotes a proactive strategy that places performance at the heart of construction management, aligning seamlessly with Lean construction principles as promoted by the Lean Construction Institute (LCI). By shifting our focus from ‘what is being delivered’ to ‘how it is being executed’, PDCM ensures a real-time, accurate measurement of progress and performance on-site, ultimately boosting predictability. This approach not only allows for the early identification and improvement of inefficiencies but also integrates Lean principles into daily workflows, making it simpler to maintain a continuous improvement mindset throughout the project lifecycle.

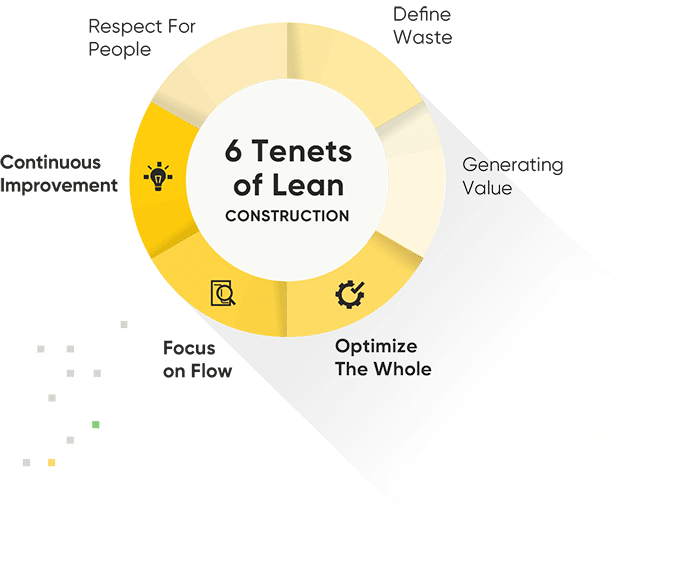

Lean construction focuses on six distinct principles that can be applied at every stage of the construction lifecycle, and by every stakeholder. Let’s look at how PDCM compliments three of those six lean construction tenets.

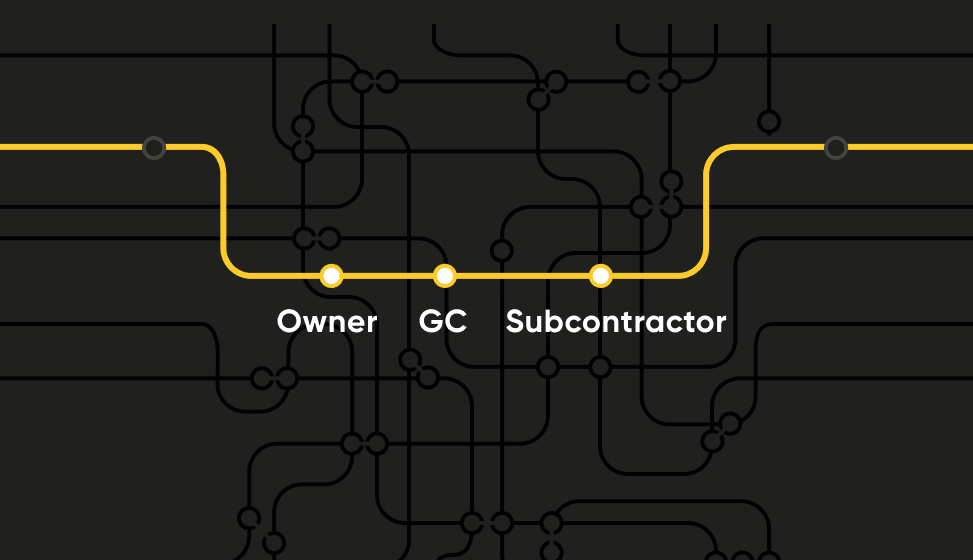

- Focus on Flow states that small delays can snowball into bigger problems due to project complexities. When one subcontractor has incomplete tasks or errors, it causes a cascade effect that affects all projected work in that area, interrupting the sequencing flow. Because the PDCM framework focuses on the interconnected features of a project, it becomes easier to recognize how each action affects others.

- The core of Optimize the Whole is that each subcontractor is responsible for not just ensuring their part of a project goes well, but that they are also working to optimize the work that comes before and after.

- Continuous Improvement says that we should constantly be looking to improve our projects and our teams, and that we should find and address any areas causing constraints. This is at the heart of the PDCM framework, where we continuously measure progress, analyze performance, and optimize productivity.

Successfully implementing both Lean and PDCM requires relevant and accurate project information. This data is the backbone of measuring, analyzing, and optimizing project metrics. Only with truly accurate data, these metrics can build a clear picture of a project’s health and empower you to deliver on time and within budget.