Embracing Digital Construction: How to Get the Most Value From Your Digital Transformation Journey

The world of construction is extremely competitive. But of course, this statement is of no surprise to those who are even slightly connected to the industry. This high level of competition means that construction companies are constantly vying for work, and doing everything in their power to stand out as the go-to solution for their potential clients.

And on the other side of the coin, clients are becoming increasingly focused on improving efficiency, cutting lifecycle costs, and doing everything they can to ensure they are getting value for their money.

But with a large section of the industry still stuck in an analog structure, many companies are starting to see the value of a structure that is focused on moving away from manual processes and instead embracing digital technology. And yet the companies that have started to adopt more digital processes may struggle to see sustainable improvements and get real added value during the project. But why?

The answer may lie in digital transformation. But what exactly is digital transformation? And how can you fully embrace it and reap the benefits of what it provides? Let’s take a closer look.

What Is Digital Transformation?

Digital transformation is the process of incorporating and integrating digital tools into all areas of a business in order to change the way they operate, to fully optimize their processes, and make them more efficient. Efficiency is a key factor in the construction industry, with 87% of construction executives and managers viewing an increase in operational efficiency as either very important or absolutely required.

When you incorporate these digital tools into your business, it is with the aim of achieving three key things:

1. Improving The Planning And Delivery Of Projects

It’s perhaps an obvious statement to make, but effective planning and delivery is crucial to the overall success of any given project. With digital designs implemented in both the planning and delivery phases, crews can experience productivity gains, and an ability to stay on track in terms of the scope as well as the budget.

With the elimination or reduction of manual processes and repeated back-and-forths in communication, and the ability to reference live plans on-site, productivity can show significant improvement.

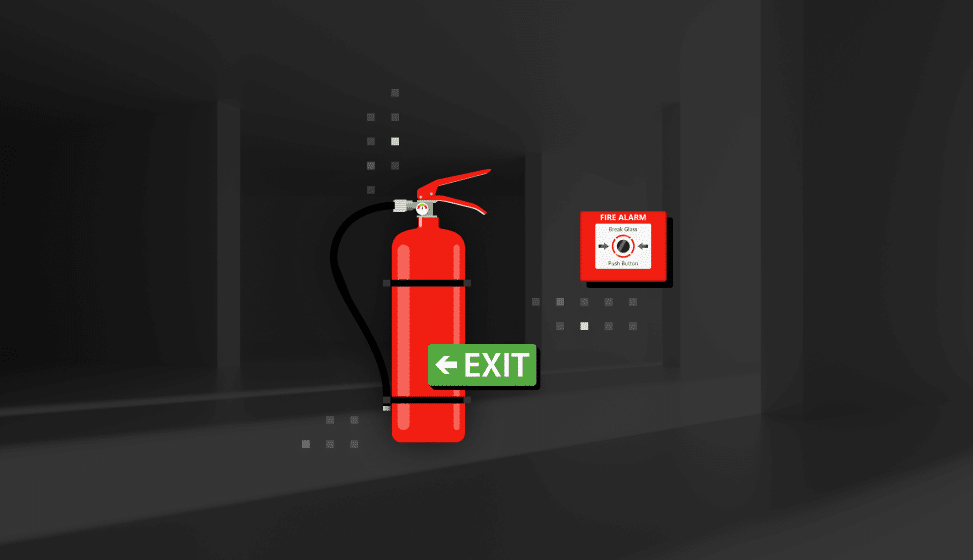

Safety and risk mitigation can also see a marked improvement with the utilization of digital tools. Of course, it is near impossible to completely eliminate risk on a construction site, but processes can always be improved.

2. Identifying And Tackling Challenges

It’s inevitable that challenges will arise throughout the lifecycle of a project. Whether that’s a lack of managers available, a shortage of workers, a case of poor data management, or even a lack of alignment throughout each stage of the project lifecycle.

Manual processes can often be vulnerable to human error, things can be missed, and issues can fall through the cracks. Digital tools can not only help tackle these challenges but actually identify them in the first place. By digitizing your processes, you can considerably reduce the number of errors, as well as create better human resources schedules that can alert you if you are lacking in manpower.

Challenges in the industry are not only what is happening with the delivery on-site, they are also in design, in procurement, in relationships, and many more.

3. Supporting Growth

As companies grow, their processes will most likely change.

The introduction of new, innovative ideas can make old structures redundant, and a growing workforce may not have a deep enough level of understanding of the way a business operates. These growing pains can put you at risk of losing control. And with this loss of control, there is a higher risk of failing to deliver on projects to the same degree of quality and consistency that you used to.

This is a common occurrence throughout construction companies that are aiming to grow from mid-sized companies with perhaps a dozen projects a year to large companies with maybe double the number of projects.

This sudden growth demands that a range of tools be put in place to ensure that you can maintain your standards – and sustain the same level of quality during any changes that take place.

Examples Of Digital Transformation

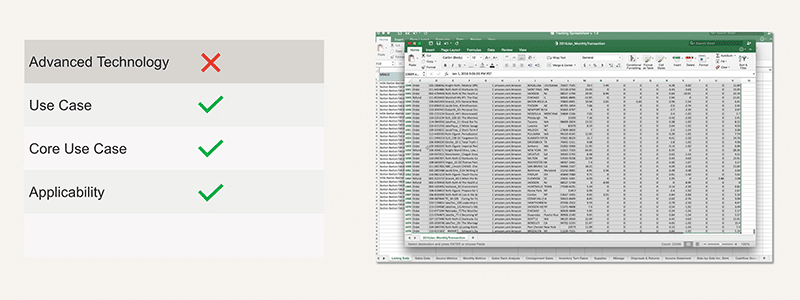

It’s important to note that there are two common misconceptions regarding digital transformation:

- It’s about innovation.

- It’s about using advanced technology.

Instead, to properly embrace digital transformation, you need to be sure any technology ticks three boxes:

- Does it have a use?

- Does it have a core use?

- Is it applicable?

Let’s take a look at two key examples of this.

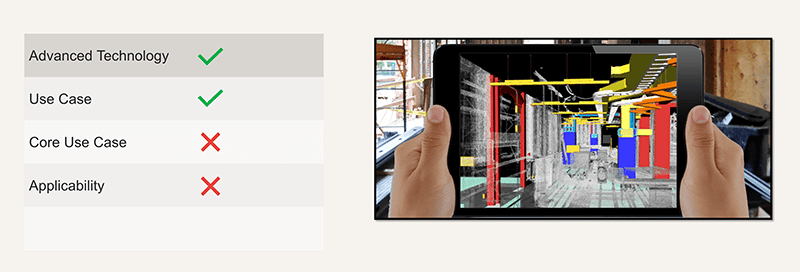

1. Augmented Reality On Projects

Augmented reality can be utilized in the construction industry in a number of ways. Perhaps the most obvious is where the user utilizes either a tablet, a phone, or a VR headset in order to see the design or model on top of the existing reality on site.

There is an obvious use for this technology, in that you can walk around the site and see how the project should play out and see if there is anything planned that doesn’t fit within the literal structure. By spotting these complications early, you can properly identify them and make the necessary adjustments – therefore eliminating the chance of costly alterations further down the line.

But when we consider whether it is a core use case that tackles a challenge that construction businesses face day to day, the answer in a sense is no. Had the answer been yes, there would have been a process that had previously been put in place that the technology was aiming to replace.

So of course, this technology has a purpose, a use, and a value – but can being able to see an augmented reality of a construction site be considered a core use, particularly when we consider the implications in terms of both the cost and time, and is it reasonably applicable? Perhaps not.

2. Excel Trackers

Now let’s take a look at an example of the complete opposite.

First off, it’s clear to see that an Excel spreadsheet is not a digital tool that would be considered advanced technology. It is a relatively simple piece of tech that is used across a number of industries.

But what we can see is that there is a clear use case, a clear core use case for analyzing information and collating reports, and it is absolutely applicable in any business’s day-to-day processes.

Therefore, using the simple tech of an Excel tracker is a perfect example of embracing digital transformation.

How Can Digital Transformation Be Harnessed?

Harnessing the power of digital transformation isn’t a quick and easy process. You don’t simply agree to digitally transform and everything automatically becomes better. It’s about taking the time to test, and then incorporating the right digital tools into your everyday processes in order to improve and streamline these processes.

This can be done in two ways.

The first is understanding what challenges you are wanting to solve and then seeking the necessary tools that will act as your solutions. Then there is the opposite method of seeing what solutions are out there, and then figuring out if these tools can help to solve challenges that you may not even realize you had.

While this may seem like a long-winded process, the big advantage of the construction industry is that it is project-based. This means that you can carry out controlled but extensive experimentation in the sense that you can trial a tool and see if it works on a project-by-project basis. This is a unique benefit of this industry and should be taken advantage of.

The Basis Of Advanced Transformation

When looking at advanced transformation, there are three pillars that should form the base upon which you can build:

- Building Information Modeling (BIM): With BIM, you are striving for what’s known as a true plan – meaning that the design that has been put in place should be built as is. This is key because when we want advanced tools to check the design, check the reality, or correlate the two, it’s imperative that the plan is consistent, and is something that a machine can easily read and fully understand.

- Common data environment (CDE): Any advanced tool that needs to know the details of a particular project will have to pull data from a source. Therefore, having a common data environment gives any tool the ability to pull data from a consolidated, singular source.

- Cloud planning/true planning: Cloud planning, or true planning, is something that is yet to be entirely embedded in the industry. Cloud planning allows planned construction scheduling to be better executed with the help of technology.

Tackling Old Problems With New Technology

Data is a gold mine for any industry – and the management and application of this data is vital for ensuring the continued success of a business. This means that there is an onus on construction managers to enable the implementation of any new technology within their workforce.

But in order to make the most of your data and its application, you need the right tools.

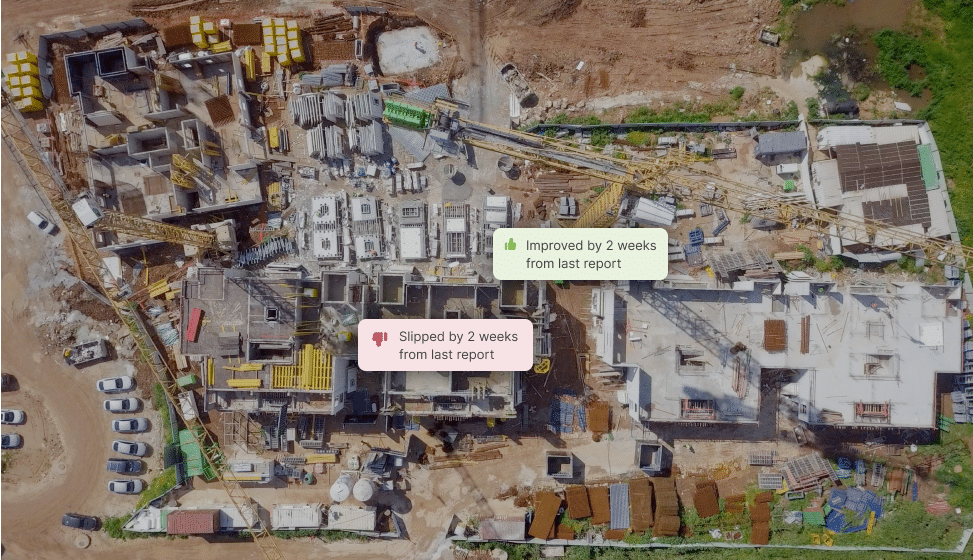

In the construction industry, control is key. And part of having control is being able to base your decisions on complete and accurate information. Having a tool like Buildots allows you to gain full control over your projects, all whilst saving valuable time and effort.

Buildots extracts the data from the BIM model, the schedule, and the site captures to provide you with accurate and meaningful reports. Giving you clarity, control, and peace of mind on your construction projects.

Webinar

Embracing Digital Construction