Why data-driven planning should be on every contractor’s radar

In construction, success or failure is often decided long before anyone sets foot on site. The early decisions made during bidding and preconstruction set the tone for everything that follows. From the level of risk you carry to the confidence you project to the client, and ultimately, the results you deliver.

Today, contractors are under growing pressure to prove not just capability, but certainty. As owners and developers gain access to richer, more objective information, the industry is shifting from price to proof. In other words, winning work isn’t just about being the lowest bidder – but demonstrating control, credibility, and a clear understanding of what it’ll take to deliver.

From guesswork to decisions grounded in reality

Traditional bidding often relies on experience, gut feel, and internal benchmarks that may be years out of date. It’s not that those instincts aren’t valuable (they are and always will be!), but without objective context, they leave too much room for assumptions.

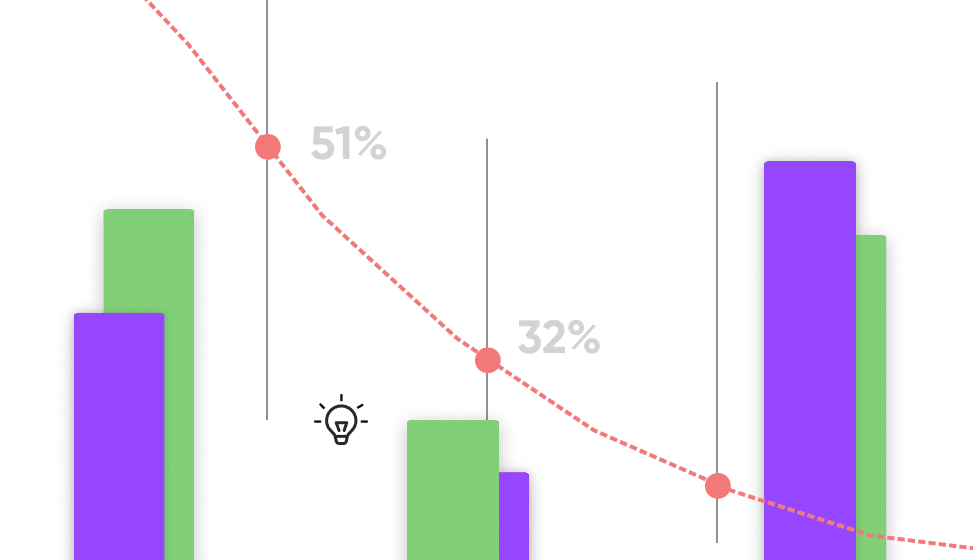

Real historical performance data gives contractors a solid, evidence-based foundation for their bids, grounded in how similar projects have actually performed – not how we hope they will. With this insight, teams can more accurately quantify risks and set appropriate contingencies.

It also transforms how contractors work with the supply chain. When you can benchmark subcontractor quotes against reliable data, unrealistic pricing stands out early. That helps avoid the common trap of accepting a low bid that hides missed scope or later disputes.

Schedules that stand up

Once the bid is won, the challenge shifts to building out a detailed schedule. Today, most project schedules are developed based on teams’ past experience. Many companies maintain internal benchmarks to estimate the duration of their schedules, but these are rarely updated and serve as little more than rough guidelines.

During preconstruction, most teams focus on creating a high-level schedule that’s ‘good enough’ to win the work and make initial commitments. It’s rarely practical to invest the time and cost required to build a detailed schedule before the project is awarded. Once commitments are made, the real schedule is then developed – often working backward to ‘fit’ the expectations set early on.

That’s why so many projects start with schedules that everyone quietly knows are unrealistic. Once commitments are made, there’s little room to recalibrate.

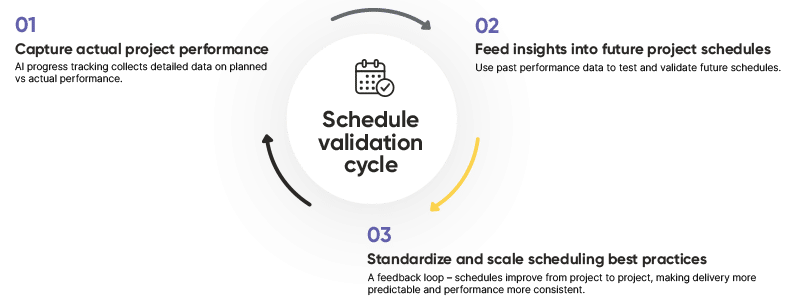

Luckily, there’s a potential alternative. By anchoring schedules in real-world historical performance data, contractors can validate activity durations and planned production rates before the first pour or install. Comparing planned pace against data from similar projects helps expose anomalies – whether it’s a trade’s aggressive timeline, an underestimated dependency, or a workflow that’s unlikely to hold up in the field.

Turning insight into advantage

Every bid, every schedule, and every project becomes stronger when decisions are backed by data. It’s the difference between managing by assumption and managing by evidence.

We explore that shift in more detail in our construction company’s guide to data, which outlines eight practical ways teams are using performance data to prevent delays and improve predictability across planning and delivery. Download it here.