What Can We Expect From The Construction Industry In 2024?

2024 is off to a busy start, but with many construction companies suffering the consequences of rising material costs, a shortage of labour and a recession which is now predicted to last until 20251, what changes can we expect from the year ahead?

We spoke to some prominent figures from two of the UK’s leading construction companies to find out their thoughts on the industry’s themes, challenges and solutions.

The Challenges…

The construction industry is renowned for its small margins and highly complex nature, which were a common theme for our experts when questioned about the biggest challenges they envisage will affect the industry throughout the year.

Mark Tant, Former Managing Director of Wates Construction, commented; “The industry neither provides viable construction costs, nor are the returns available to those within the industry sustainable. Insolvencies throughout the sector are running at record levels. Combine this with a chronic skills shortage, an aging population, and a disparate group of interested parties involved in every construction project, without aligned end objectives.”.

Nick Leach, Director of Digital Construction at Sir Robert McAlpine, also expects the supply chain challenges that started in 2023 to persist throughout 2024 – “having enough competent and experienced resources available to deliver projects and meet the demand of the industry will be fundamental.”.

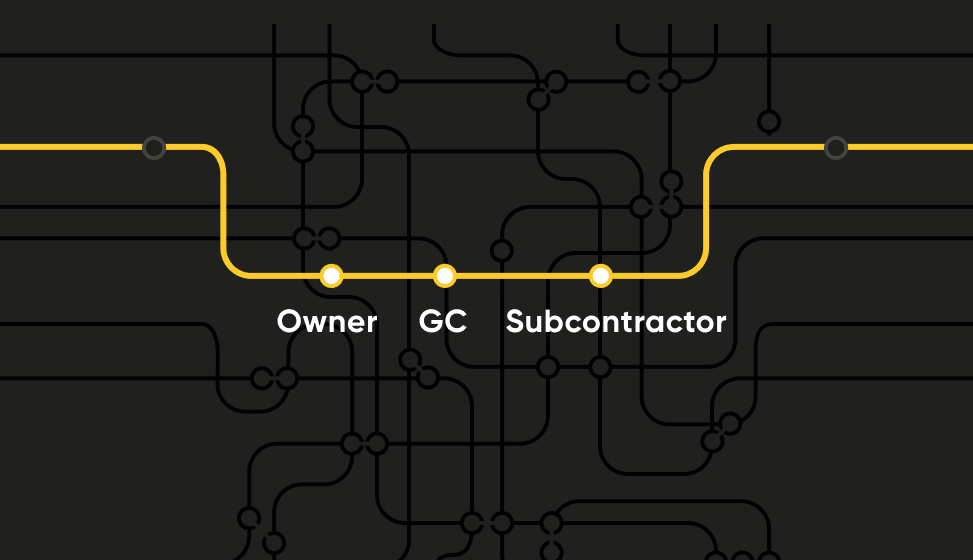

When running successful construction projects, people are the key. Collaboration and alignment with the wider supply chain is essential. It’s no longer good enough for teams to work in silos with no consideration for how their performance will affect their successors. Everyone involved in the project should be working towards a shared goal of growth, quality, efficiency and transparency in order to maximise project outcomes.

The Emergence Of The Building Safety Act…

The Building Safety Act and its influence on the development of new high rise residential schemes is already having an undeniable impact on the industry, but both Mark and Nick see this as a great positive rather than a challenge. This shift to full transparency and accountability is how the industry should have been working for years; “it simply reflects good practice in construction – have a good regime of installation, inspection and record keeping,” says Mark.

Nick adds that “the need for having an audit trail and better project management is driving businesses to prioritise how they digitalise their information management records. In addition, the need and importance for having and demonstrating technical competency records of internal and external staff utilising digital technology will support organisations and mitigate risk in the long term.”

At Sir Robert McAlpine, the business has set up its own competency solution to measure employees across the business, and are working on further frameworks to measure digital, sustainability, H&S, planning, commercial and more, in order to set benchmarks and provide gap analysis for training and support. This mentality is crucial to setting up your business for success and fostering a culture of growth and support.

The Drive For Better Sustainability…

Another hugely important theme that is gaining its rightful prominence in the industry is sustainability. With the built environment accounting for ⅓ of all CO2 emissions2, it’s imperative that we work together to reduce the carbon footprint of our schemes, starting with the build, through to the long-term operation. More can be done to increase productivity and accuracy on-site in order to reduce wastage and, in turn, carbon emissions. Mark expects this drive to be one of the “biggest focus areas” for the industry as it progresses towards Net Zero Carbon.

Find out more about the need for objective data when delivering a sustainable scheme in our recent blog.

How Do We Tackle These Challenges?..

When it comes to the skills and labor shortage, one answer, Mark suggests, could be investing in a “people plan”. With the chronic skills shortage at all levels, from management to trades, Mark feels it’s important to undo the culture of man-marking on projects, and set both the people and projects up to succeed. The key to this being to “align objectives, understand the deliverables, and confront the risks”, as well as engaging the key parties to understand the economics of sustainable construction, and joining up capital and operating costs where you can.

Nick believes that long-term collaboration will also be key to unlocking a project’s full potential, through “building deeper frameworks with the right supply chain partners and, in turn, providing the supply chain with repeat opportunities”.

Once there’s a good foundation between the people working on your projects, it’s time to combine that with another fundamental solution: investing in a digital foundation and using data to drive better decision making. “Technology is fundamental to modern construction. A fully joined up technology driven approach will drive better construction projects.”, says Mark, who believes that successful technology is rooted in an effective BIM model, federated into the supply chain, and providing a joint cost, programme and quality regime.

“The need for construction to embrace technology to improve efficiency and quality is not new, but the industry has not yet managed to join up their processes to give a better customer experience.” By embedding technologies into a company’s operations; design, project planning, safety, quality and record keeping (incorporating Golden Thread), we will be able to “enhance the reputation of the industry.”.

This sentiment is supported by Nick, who urges supply chains to get on board with “upskilling themselves in technology and digital transformation to mitigate the effects of the labor shortage.”. He found that Sir Robert McAlpine, as a Tier 1 contractor, has seen huge benefit in opening up their digital tools and making them accessible through internal learning and sharing programmes. He believes that this will play a crucial role in supporting the supply chain to upskill. There are also dedicated organisations like the Supply Chain Sustainability School, which provides open content and material on digital learning and measurable maturity tools to support gap analysis and business case proposals.

So, Where Does AI Come Into It?…

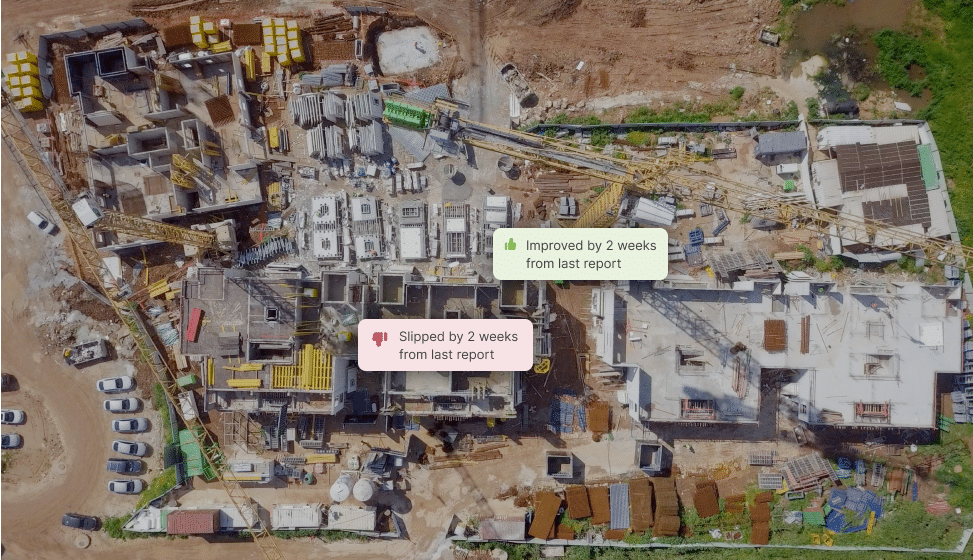

When quizzed about the importance of Artificial Intelligence in maximising the output of the industry, both of our experts believe it will play a pivotal role, but Mark points out that “the extent that it grows will be only limited by the ability of the industry to adopt it”, so it’s instrumental that businesses get on board in order to augment its potential. Mark sees AI as being instrumental in crafting bid responses, as well as developing generative design solutions for standardised products or elements in education, health, and housing.

Nick sees more value in AI that aims to reduce admin tasks. “As an industry, there are still a great deal of traditional methods used in creating and finding information. AI can reduce that reliance and burden, freeing up people's time to work on and use their expertise and skills on tasks where time can be better spent.”. He also believes that it will enhance greater insights for businesses allowing more transparency on how they are operating and delivering, and how people and projects are performing.

“The industry will need to adapt and prepare how their businesses will operate with respect to AI quickly in order to harness efficiencies and drive more competitive edge,” but, as many look to adopt this new technology that is revolutionising the industry, he suggests that implementation and inclusion of the right governance and regulations will need to be embedded in order to support positive and ethical use of AI.

Whilst there is a lot of noise in the industry, it’s a time where there is a lot of opportunity available. We have plenty of room to grow when it comes to sustainability, quality, collaboration, accountability, safety and planning. It’s time that we lean on the array of technologies available to us in order to maximise our potential, and the potential of our buildings as we continue to sculpt a greener, healthier and more sustainable world for the future.

—

About Buildots

Buildots, an award-winning leader in construction technology, leverages AI and computer vision to upgrade traditional project management methods, introducing a performance-driven approach to managing construction projects. Our platform automatically generates accurate, unbiased data and actionable metrics crucial for strategic decision-making.

Find out more about our platform here.

—