Digital Accuracy Meets Reality Build Group’s Success With Buildots

Build Group's journey with Buildots stands as a testament to the construction industry's ongoing evolution and it highlights how Buildots can transform any construction project with the help of true progress data. That’s why we are happy that Build Group’s success of adopting our solution for their M2 project paved the way for two more joint endeavors: A mixed-use 48-story tower in Seattle and a student housing initiative in San Francisco, all of them reporting improved levels of on-site efficiency.

As the construction industry propels toward the future, a theme emerges: The need for unyielding project control. But the complexity of every project demands solutions beyond traditional site walks and weekly trades meetings: “The manual process is tedious for us”, says Chad Krause, Vice President of Operations at Build Group, when sitting down with ENR to discuss the challenges Build Group is facing.

“It’s very time-consuming to send personnel to the jobsite and track everything on the job, marking it off on an iPad ”, Krause explains in the extensive interview. His statement echoes a sentiment shared by many construction professionals who, like Build Group, found themselves relying on on-site staff to document progress and identify errors, often leading to delays and budget overruns.

Continued Partnership For Success

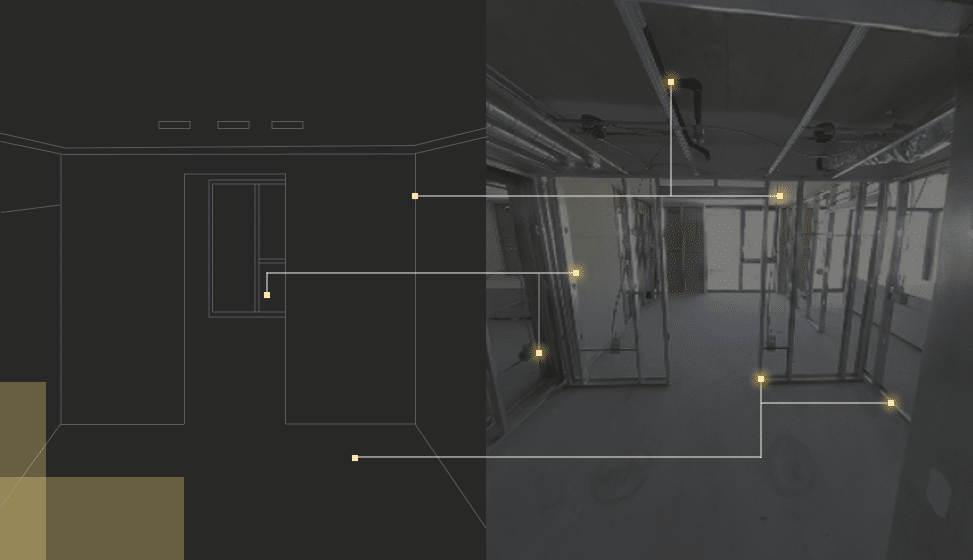

Seeking a remedy, Build Group kickstarted their engagement with Buildots by piloting it on the M2 mixed-use parcel within the 5M development in San Francisco – a soaring 22-story structure of 288 units spanning a total 600,000 SF.

Building with Real-Time Intelligence

Buildots automated reports and real-time alerts created a brand new synergy between plans and reality, resulting in greater visibility for Build Group overall: “Everyone likes to be better informed, from the GC to the subcontractors. If there is a portion of the job that is falling behind, they’ll want to know about it”, tells Krause, remarking: “Anything we can do to improve efficiency on the GC and the subcontractor sides is generally a good thing.”

“We’re trying to free the information”

Easily gathering insights from the jobsite was a key advantage, as Krause emphasizes: “The information would never get to the top, it would be stuck at the jobsite level”, he asserts, pointing to the benefit of sharing a single source of truth of actionable progress data with all stakeholders and management. With time and information freed up, both site teams and management can turn their attention to more high-value tasks and high-stake decisions, both equally challenging without having an accurate dataset at hand: “We’re trying to free the information to make more informed decisions”, concludes Krause.

Click here to learn how Mace & Wates managed to enhance their delivery with better controls.

This content is based on the insights from a recent article in ENR. ENR, Engineering News-Record is an American weekly magazine that provides news, analysis, data and opinion for the construction industry worldwide. It is widely regarded as one of the construction industry's most authoritative publications.