Construction delays How Technology Is Battling 4 Common Causes Of Construction Delays

It’s the eternal dilemma that all project managers face: how do you track the hundreds of different moving parts involved with every project, while still keeping an eye on the big picture? How do you gather enough detail to spot problems quickly, while still being able to take a step back and consider how they might affect the project as a whole?

Project managers are increasingly finding that, if they want to find this balance, they need to implement new technology for their construction sites and their back offices. It’s hardly surprising that the 2021 Global Construction Survey found that 84% of construction business operators and contractors are planning to invest moderately or heavily in technology.Let’s take a look at how the latest innovations can help project managers identify errors sooner, so they can respond faster.

Monitoring equipment with IoT sensors

If a piece of equipment malfunctions or goes missing, the entire site can grind to a halt -and, if it’s not repaired or recovered, you could be facing huge costs for replacing it. But tools are always on the move and frequently in use, sometimes by several different people on a site in the course of a day. So how do project managers keep track of their most delicate or expensive assets, without having to spend hours manually checking every piece of equipment? Many companies are now embedding IoT technology into their construction equipment to help solve this problem.

First, IoT sensors and GPS trackers can be used to track the location of equipment and vehicles. This means that, if a piece of equipment is lost or stolen, project managers can quickly and efficiently track it down and either retrieve it or report its location to the police.But this is only scratching the surface of IoT’s potential: with the right sensors, you can collect real-time data on the performance of each piece of equipment on your site. Instead of manually inspecting each machine, or pulling logs from the equipment’s internal computer, you can see a live feed that shows how the tool is performing. Is it operating efficiently? Is it due for maintenance? Are there signs — like overheating or excessive vibrations — that it might need emergency maintenance?

With this new level of data, you can go beyond identifying problems with your equipment and instead predict and fix problems before they even occur. In doing so, you can avoid hold-ups from malfunctioning machines and even prolong the life of your machinery by keeping it in the best possible condition.

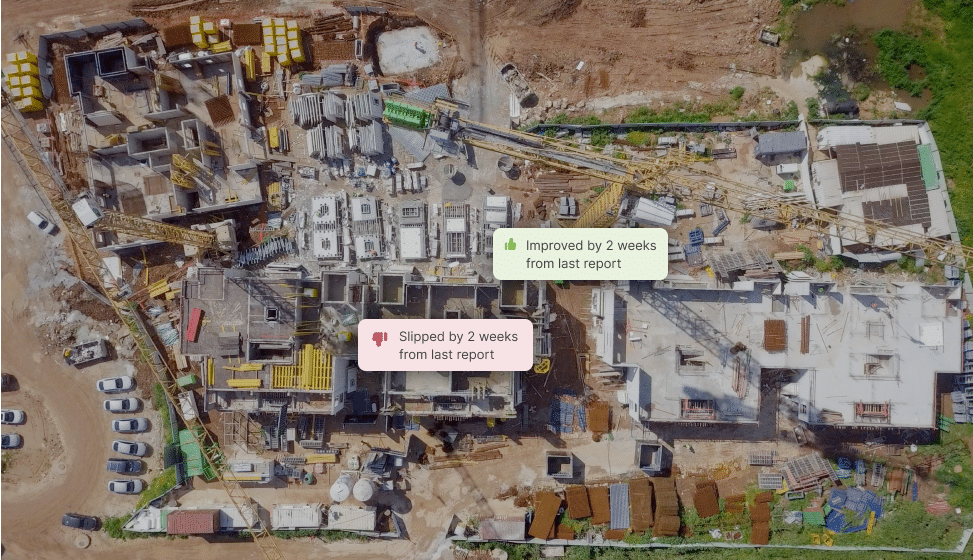

Monitoring productivity with regular surveys

As a project manager, you’re always trying to build a clear picture of yourprogress:

- How far your project has come

- How far you have left to go

- Whether or not you’re likely to hit your milestones on time.

It’s tempting to try and monitor the productivity of your sub-contractors by monitoring worker activity. Some project managers try to track this on a macro-level, by looking at how many workers are on-site each day, while others focus on the micro-level by using IoT technology to assess the activity of individual workers.

But this doesn’t necessarily give you a good picture of whether your project is running efficiently. For one thing, constantly monitoring the productivity of employees can be demoralizing and counter-productive. For another, the number of workers on-site – or the amount of time they spend working vs. relaxing – isn’t directly related to the progress of your project. Workers could be incredibly active all day long, but still be working inefficiently.

Instead, project managers are using technology that lets them assess how many tasks have been completed in a given timeframe and measure that progress against their project plans. Buildots does this by providing on-site teams with cameras that gather a 360° view of the construction site. Once the footage is compared with the project’s BIM and schedule, Buildots’ AI then assesses how much of the work has already been completed, and what still needs to be done. Using this data, Buildots can then compare the progress made so far with the project manager’s original Gantt chart or timeline. By completing this process regularly, you can watch closely for any signs that the schedule might be slipping. With that information in hand, you can identify the source of the hold-up – whether that’s inaccurate forecasting, unavoidable delays, or issues with individual sub-contractors – and figure out how to get the project back on schedule.

Whitepaper

Build Smarter – Get Your Job Done Efficiently

Keeping employees safer on-site with smart wearables

Between electricity, airborne fibers and toxins, slips and trips, moving objects and a host of other hazards, construction sites can be a dangerous place to be. In addition to doing everything they can to prevent accidents, it’s also vital that project managers can detect and address any incidents that do occur. That’s why many project managers are exploring how ‘wearables’ — tracking technology worn by workers on-site — can help keep the head office informed whenever someone is injured or put at risk.

These wearables can take many forms. It might be a device worn on a worker’s wrist, which alerts someone if the device drops suddenly, indicating a fall. Or SolePower’s work boots, which track worker fatigue and log any trips or stumbles. Even big players like Caterpillar are exploring new safety technology: they’re working on RFID tech that monitors the rest and activity cycles of individual workers, so that project managers can catch when someone has gone too long without a break. With this kind of technology, it’s easy to keep project managers in the loop whenever safety issues do occur, so they can send help quickly and prevent similar problems from occurring in the future.

Using AI to identify errors or missing elements

- Errors happen. Fixtures are missed out, things get installed incorrectly, plans are misread. Considering that the average apartment contains around 300 different elements, it’s almost impossible for a project manager to manually review and approve every single one. But the longer errors go unnoticed, the bigger the problem becomes. A window in the wrong place is easily moved if you’ve only installed the first-fix frame but can cost you thousands of pounds if you only notice it after you’ve plastered and finished. A missing light switch can be added with no trouble if the electrician is still on-site, but trying to add one when the electrician left for another job weeks ago could cause massive disruption.

- Just as Buildots’ AI helps project managers assess how much of the work has been completed, it can also use 360° camera footage to identify errors and missing elements early on. After each stage of the project, you can provide one of your team with a head-mounted camera, send them on a walkthrough of your site, and then use Buildots AI to compare the footage with the original drawings in your BIM. If anything’s missing or incorrect, the AI will flag it immediately, so you can work with your on-site teams to get it fixed faster.

How can technology take the uncertainty out of your construction projects?

Technology isn’t just changing the way project managers find and solve problems on construction sites — it’s transforming construction sites from start to finish. Want to find out how technology is making every stage of the construction process safer, more efficient and more accurate? Read our guide,‘Build Smarter – How Tech is Helping Construction Face Five of its Biggest Paid Points’ to see examples of the latest technology in action.