How is AI solving the labor shortage in mission critical construction?

The construction industry is hurtling toward a crisis. According to the U.S. Bureau of Labor Statistics, more than 40% of U.S. construction workers are expected to retire by 2031, taking with them a lot of institutional knowledge. Contractors are feeling the pressure, yet attracting new talent isn’t getting easier, partially because younger workers continue to view the industry as outdated, high-stress, and slow to modernize.

In the mission critical space, the labor shortage is being compounded by a construction boom. A surge in data center and semiconductor fab construction, catalyzed by the AI revolution, is placing extraordinary additional pressure on the construction workforce.

For contractors and owners, this creates an enormous challenge. But there’s also an opportunity to become more efficient. That’s because, while AI is one of the forces fueling mission critical construction demand, it also presents solutions to the construction labor shortage – especially when applied through AI-driven project controls.

Automating reporting

Let’s start with the most fundamental way AI can help tackle the labor shortage – automating manual reporting so skilled professionals can focus on higher-value activities. It’s a familiar story across industries. In construction, AI does far more than just replicate tasks that were once done manually. It unlocks a new level of detail, objectivity, and granularity that simply wasn’t possible before. This is especially critical on mission-driven projects, where trying to manually track the installation of millions of individual elements would be not only impractical, but impossible.

Traditionally, compiling construction progress reports has required hours of site walks, note-taking and updating spreadsheets – tasks often done by the same people responsible for managing delivery. AI-powered platforms, such as Buildots, offer an alternative. By capturing regular site imagery and using AI to compare that imagery with the 3D model and construction schedule, users receive an accurate, up-to-date picture of the project's status, down to the individual trade, activity, and element.

On one large-scale hospital project delivered by the contractor IHP, the time savings were immediate. “There is no doubt about it; having Buildots has saved 2–3 person days per week to gather the progress data for review in collaborative meetings and input into the monthly reports,” said Lee Howlett, Planner (scheduler) at IHP.

That experience was echoed by the team at the GTM Sud-Ouest TP GC consortium (a VINCI Construction subsidiary) and SOCOTRAP, who saw a 66% drop in time spent on manual data collection during the fit-out of an aeronautical assembly line, thanks to AI progress tracking.

Intel – which has adopted AI progress tracking to support its global semiconductor fab construction program – saw similar benefits. By reducing the demand for hard-to-fill commercial team (quantity surveying) roles by more than 50%, the company was able to reallocate resources more effectively, with plans to extend the approach to commissioning teams.

Turn expertise into a scalable asset

An underestimated consequence of the construction labor shortage is the quiet erosion of institutional knowledge. As seasoned professionals retire, the hard-won lessons they carry risk disappearing, leaving firms vulnerable to repeating the same costly mistakes on future projects.

With AI-driven systems, experienced team members can capture and embed proven processes. This allows less experienced staff to confidently handle complex tasks, effectively multiplying the capabilities of the entire workforce. The result is a ‘force multiplier’ effect, where expertise doesn’t just stay with a few individuals but elevates everyone, even in times of scarce skilled labor.

AI can transform every job site into a learning engine. One example of this we often see at Buildots is using past project data to optimize sequencing across projects. It’s especially powerful in highly repeatable mission critical builds like data centers.

Maximize onsite time through accurate, actionable data

On mission critical construction projects, every hour onsite counts. Yet too often, highly skilled professionals spend a large portion of their day hunting down information, walking the site to verify installations, cross-referencing drawings, and chasing updates. The result? Less time spent actually resolving issues and driving the project forward.

AI progress tracking flips that equation, arming teams with precise insights into what needs to be done and where, before they even set foot on the job site.

This shift delivers real, measurable impact: projects using AI-driven progress tracking see significantly more productive time on site. There are several reasons behind this. Crews arrive knowing exactly which areas are ready for work, avoiding costly clashes. In addition, unfinished tasks are automatically flagged, meaning trades leave fewer jobs “almost done.” The result is fewer return visits, less rework, and a smoother path to completion.

Stop wasting labor on preventable rework

In construction, rework is both costly and labor-intensive. The best way to avoid it is to catch issues before they snowball. Buildots makes this possible by enabling teams to verify that every element is installed exactly as designed before sign-off. This proactive, data-driven approach catches errors early, dramatically reducing costly rework later in the project.

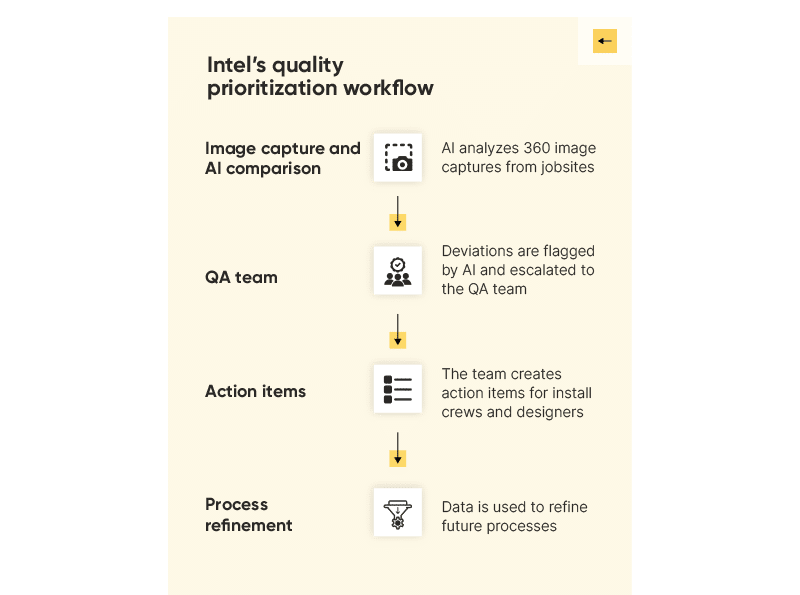

Intel’s global semiconductor fab program demonstrates the power of reducing rework via an AI-powered quality control workflow. AI analyzes image captures from jobsites to flag potential errors as early as possible. These are escalated to Intel’s QA team, which determines the necessary action items. This data is then used to avoid repeating the same mistakes on future projects by updating designs, clarifying communication with subcontractors or creating new, more effective processes.

Improving first-time quality ensures limited labor resources and in-demand trades aren’t wasted on fixing preventable issues. The results speak for themselves, including 4.3% saved in rework and an average timeline reduction of four weeks per fab.

The bottom line: Doing more with less, and doing it better

The industry can’t hire its way out of the labor crisis. But it can adapt. And mission critical projects, with their repeatable design, tight timelines and zero-margin-for-error delivery models, are showing what that adaptation looks like.

AI progress tracking platforms offer a scalable, proven way to improve efficiency and transform how construction teams plan, execute, and learn. Perhaps more importantly, they also represent a shift toward a more modern, data-driven construction culture – one that’s more attractive to the next generation of builders. This new approach promises fewer unnecessary hours worked. Fewer last-minute scrambles.

More time spent building, less time explaining.

Ready to see how AI can help your team do more with less? Book a Buildots demo today and see what performance-driven construction looks like in action.