Tackling Data Process Management In Construction

The average construction project includes over a dozen sub-contractors, working on a one-of-a-kind site that changes (physically) every week. No other industry has a manufacturing process in which the environment and people are so dynamic. These conditions create unique process management challenges, but the goal remains the same. If you want to maximize your profits and minimise your risks you need to know exactly what is happening on your site at any given time – and that means having access to data to inform process management.

The industry is already using one tool to achieve this – agreed schedules, backed by Gantt charts, but in reality, each block of activity shows far too much work over far too long a period to enable you to have true control over the project. As one experienced project director told me the other day: “Having two weeks block on your Gantt for drylining on the seventh floor, means you will only realize it’s late when these two weeks are over.” Schedules on their own are a blunt instrument indeed – it’s quite common to look at the construction site spreadsheet and see vast areas of green, and then it gets closer to completion and you realize that green was actually only green-ish, and that there are lots of things still waiting to be done.

This means that the first step to true control is a detailed execution plan. One modern framework that can assist us in creating this is BIM (Building Information Model). Combining the existing Gantts with the BIM’s element-based nature can turn the project’s programme into a highly detailed execution plan. So now the activity “Dryline 7th floor” can be expanded into dozens of smaller tasks for each wall or sqm. This is by no means a simple task, (something we will save for another blog post), but it streamlines the process completely.

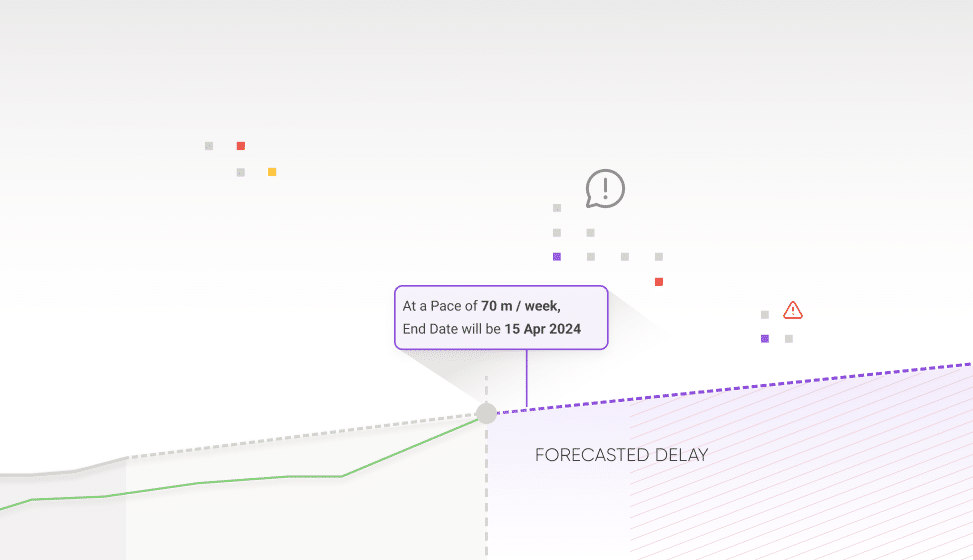

Next, we need an adequate measurement solution. To truly reap the benefits, a detailed execution plan must be complemented with more detailed and frequent tracking. With managers already struggling with the current resolution, collecting the data manually is not really an option.

At Buildots, we have given ourselves the task of tackling data process management in construction and using technology to close the project control gap. We believe that managers should manage, and technology should do the dirty job of tracking processes.

But as our CEO Roy noted in a recent feature on PlaceTech, our vision also introduces a new challenge – consuming all this data and reaching the real goal, which is of course improving the process. The key highlights for the site team are extracted from this data (such as what is on schedule and what has been missed) in order to create some actionable insights which can be immediately implemented to make daily decisions, control their processes and adapt their schedule.

As a co-founder and chief product officer at Buildots, I deal with these challenges on a daily basis. Connect with me through LinkedIn or at [email protected] if you’d like to discuss, collaborate or help us test our product – I can offer beer or coffee in return.